High-Power, Harsh Environment Connectors

TE Connectivity's AMP MCP 9.5 series connectors are high-power, two-position connectors designed for harsh environment applications in the automotive and commercial transportation industries. These environmentally sealed connectors are ideal for wire-to-board and wire-to-wire connections in applications requiring high current and power.

FILL OUT THE FORM TO READ OUR FULL INSIGHTS

Key Features:

AMP MCP 9.5 Two Position Connectors

| Features | |

|---|---|

| Environmentally Sealed |

IP67 & IP69K with backshell |

| High Current & Voltage |

Up to 78 amps and 28V DC |

| Broad Wire Compatibility |

6-10 mm² wire and 4.6-6.6mm insulation |

| Versatile Mounting |

Tool less mounting |

| Heavy-Duty Construction |

Rectangular thermoplastic housing |

| Secure Connection |

Integrated secondary lock for contact alignment |

Benefits:

AMP MCP 9.5 Two Position Connectors

- High-Power Performance: Deliver up to 78 amps with 10 mm² wire, ideal for demanding applications.

- Unwavering Reliability in Harsh Environments: Withstand extreme temperatures (-30°C to +100°C), vibration, and shock, making them perfect for demanding industrial and transportation settings.

- Maximum Versatility: Choose from diverse mounting options – inline, flange, sealed flange, and PCB mount – for optimal flexibility in your design.

- Secure & Reliable Connections: Integrated secondary lock guarantees precise contact alignment and retention, while the tool-free slide lock ensures effortless mating.

- Unmatched Protection: IP67 and IP69K rated sealing with backshell safeguards against dust, moisture, and even high-pressure washdowns.

- Built to Last: The heavy-duty thermoplastic construction provides superior durability in harsh environments.

- Simplified Design & Assembly: Common part numbers for housings, contacts, seals, backshells, and tools streamline design and simplify assembly processes.

Real World Applications

The AMP MCP 9.5 connectors excel in various real-world applications where high power, reliability, and resilience are crucial. Here are some prominent examples:

Automotive & Commercial Transportation:

- Engine & Transmission Systems: Connecting high-current components like alternators, starter motors, and battery cables.

- Power Distribution Units (PDUs): Ensuring reliable power delivery within the vehicle's electrical system.

- Off-Highway Vehicles: Withstanding demanding environments in construction equipment, agricultural machinery, and heavy-duty trucks.

Industrial Applications:

- Industrial Automation & Control Systems: Connecting sensors, actuators, and other critical components in harsh factory environments.

- Robotics & Automation: Supplying power and signals to robotic arms, grippers, and other automated equipment.

- Oil & Gas Industry: Delivering reliable power and control signals in drilling rigs, refineries, and other oil and gas applications.

Additional Applications:

- Commercial Transportation: Powering onboard systems in buses, trains, and marine vessels.

- Renewable Energy: Connecting solar panels, wind turbines, and other renewable energy sources to control systems and power grids.

- Any application: Requiring high-power connections in demanding environments with extreme temperatures, vibration, shock, dust, moisture, or high-pressure washdowns.

Frequently Asked Questions

Q: What is an AMP MCP 9.5 two position connector?

A: TE Connectivity’s AMP MCP 9.5 two position connectors are environmentally sealed and designed for cable to cable and cable to board applications. AMP MCP 9.5 two position connectors are used in harsh environment applications where even a small degradation in connection may be critical.

Q: What are the appropriate applications for AMP MCP 9.5 two position connectors?

A: Truck, Bus, Off-highway, Construction, Agriculture, Mining, Emergency Vehicles, Forestry, Recreational, and Marine

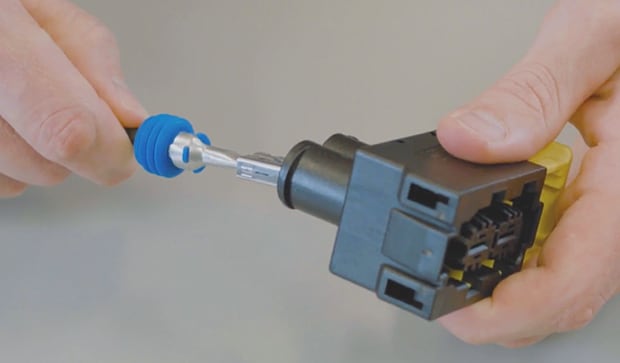

Q: When should I use AMP MCP 9.5 two position connectors?

A: AMP MCP 9.5 two position connectors provide reliability and performance on the chassis, gearbox, actuators, and hydraulic pump. AMP MCP 9.5 two position connectors offer field proven reliability and rugged quality. Rectangular, thermoplastic housings offer a wide operating temperature range and silicone rear wire and interface seals allow the connectors to withstand conditions of extreme temperature and moisture. The connectors feature an integrated slide lock for mating and integrated secondary locking device for contact alignment and retention.