Built for Power

High current interconnect (HCI) connectors can be used anywhere a signal or high power needs to be routed through a device. These wire-to-board and wire-to-wire HCI connectors are available in 4.0mm and 6.2mm centerline pitch. The connector system offers straight connector mounting, and the square-peg technology helps to enable product capability with industry standard products. If your application has more than one printed circuit board then HCI products are an option to connect the PCBs.

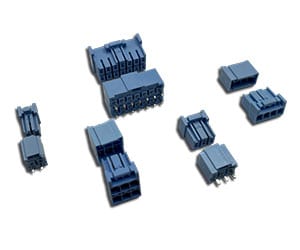

New HCI High-Current Interconnects

Designed for high-current applications

- Provides current rating up to 20A.

- Square-peg technology helps to enable product compatibility with industry standard products.

Rugged

- UV-resistant thermoplastic material for enhanced connector performance, helping reduce risk of early degradation and increasing mating cycles

- Suitable for use in harsh environments.

Reliable connection

- Secure locking feature helps prevents accidental unmating.

- Housing and receptacle are keyed and color-matched to assist with proper mating.

Product Features

High Current Interconnects (HCI)

- 4.0mm and 6.2mm centerline.

- Straight PCB mount.

- Square termination posts.

- Reaches up to 20 A.

Product Benefits

High Current Interconnects (HCI)

- Provides design flexibility.

- Cost effective wire-to-board and wire-to-wire connectivity.

- Keying helps ensure proper orientation of parts when assembled.

- Enables inter-changeability with industry standard designs

FLEX

Design Flexibility

LOCK

HCI connectors feature a locking mechanism to ensure positive mating.

DENSE

Compact, economical solution for high density wiring connections

High current interconnect (HCI) connectors can be used where anywhere a signal or high power needs to be routed through a device. These wire-to-board and wire-to-wire HCI connectors are available in 4.0mm and 6.2mm centerline pitch. The connector system offers straight connector mounting, and the square-peg technology helps to enable product capability with industry standard products. If your application has more than one printed circuit board then HCI products are an option to connect the PCBs

Components: A Complete Solution

Wire to Board

A typical wire-to-board interconnect solution requires a raw discrete wire that is connected to a contact that is then inserted in the housing, and finally mated with a header that is terminated to a PCB. For HCI wire-to-board connections, the raw discrete wire is either inserted in the socket or pin contact. The socket contact is inserted into the plug housing and mated with the receptacl

header that has pre-loaded pin contacts.

4.0mm

- Raw Discrete Wire (AWG 26-16)

- Contact: 2420268-X

- Housing: Y-2420266-X

- Header: Y-2423324-X

6.2mm

- Raw Discrete Wire (AWG 20-12)

- Contact: 2408841-X (Pin) and Housing: Y-2408818-X (Receptacle)

- Contact: 2408840-X (Socket) and Housing: Y-2408780-X (Plug)

- Header: Y-2408753-X

Wire-to-Wire

(6.2mm only): A typical wire-to-wire interconnect solution requires a raw discrete wire that is connected to a contact that is thenContact: 2408841-X (Pin) and Housing: Y-2408818-X (Receptacle) inserted in the housing and mated with a similar housing that also has a contact inserted. For HCI specifically, the receptacle housing is connected to the pin contact and the plug housing is connected to the socket contact, then the plug housing is mated with the receptacle housing.

- Raw Discrete Wire (AWG 20-12)

- Contact: 2408841-X (Pin) and Housing: Y-2408818-X (Receptacle)

- Contact: 2408840-X (Socket) and Housing (Plug): Y-2408780-X (Plug)

HCI Attributes

PCB Mount Orientation

- Depends on the direction that the housing mates with the PCB header

- Straight: The housing is mated perpendicular to the PCB

Termination Methods to PCB

- Depends on how the PCB header is applied to a PCB

- Through hole (DIP): All HCI 4.0 mm and 6.2 mm headers are attached to the PCB by inserting PCB tines into the pre-drilled holes in the PCB and then soldering on the bottom side of the board

Square Termination Posts

- Allows competing parts to be interchangeable with TE’s HCI parts.

Frequently Asked Questions

Q: What gauge wire (AWG) will you be using?

A: TE’s HCI product accepts 16-26 AWG discrete wire for the 4.0mm centerline pitch and 12-22 AWG discrete wire for the 6.2mm centerline pitch. Remember that the higher the AWG measurement number, the smaller the discrete wire. For example, 12 AWG is larger than 16 AWG, meaning that 12 AWG will have higher current carrying power.

Q: Does your device require higher current and what is voltage than available with HPI?

A: HCI can be used to transfer signal or high power up to 12A and 300V for the 4.0mm centerline pitch and 20A and 600V for the 6.2mm centerline pitch. Both the 4.0mm and 6.2mm centerline pitch support a higher current than HPI.

Q: Does your application require a locking or keying feature to strengthen the mating connection between the HCI components?

A: If your application requires a secure mating retention feature or keying, TE’s 4.0mm and 6.2mm HCI product line offer A,B, and C type keying or external/internal locking features respectively to improve the reliability of the interconnect system.

e

e

e

e

e

e

e

e

e

e

e

e

e

e