-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

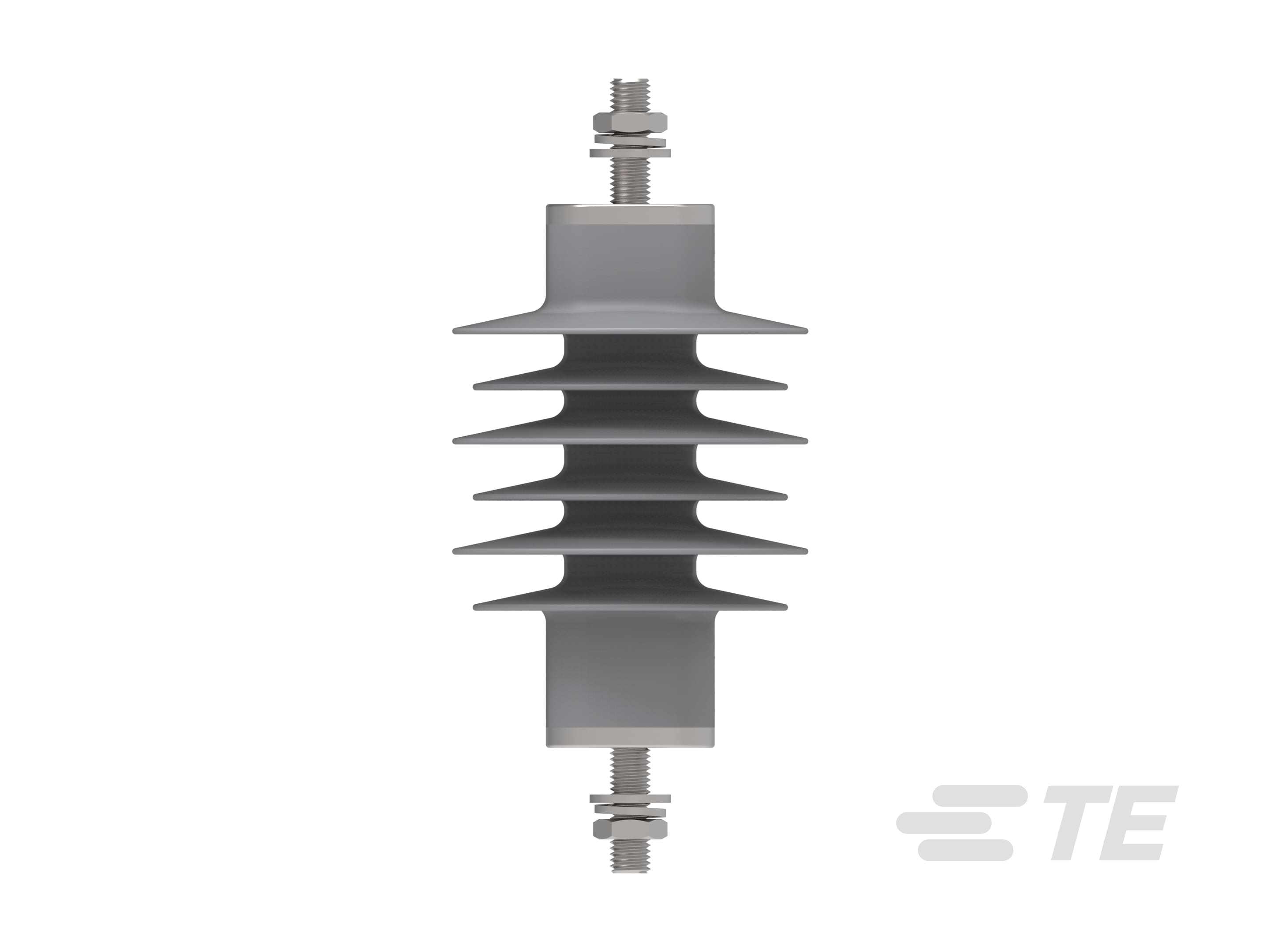

Polymeric Surge Arresters for Distribution Networks

- Bowthorpe

- Bowthorpe DOV

Product Features

-

Power Component Application Type : Distribution

-

Product Availability : Worldwide

-

Core Type : Cage

-

Cantilever Strength -SSL (kN): 225

-

Product Height (mm): 160 | 229 | 258 | 298

-

Product Height (in): 6.299 | 6.299 | 9.016 | 9.016 | 10.157 | 10.157 | 11.732

Available from

Our Bowthorpe DOV Distribution Surge Arresters: Proven in-field service experience across the globe since the early 80’s using our pioneered polymeric composite molded housing.

Our Bowthorpe DOV Distribution Surge Arresters have been designed and tested to meet our customers' tough environmental conditions. Tests were carried out on these surge arresters under the supervision of independent and accredited European test laboratories to meet the requirements of the latest edition of the IEC 60099-4 standard. These products are the latest gapless, zinc oxide surge arrester family from our Bowthorpe EMP range. They are manufactured using high-quality ZnO varistors, which display excellent thermal and current handling characteristics due to the guaranteed homogeneity of the varistor volume. The Distribution Surge Arrester’s crimped structural construction ensures lightweight products with optimal mechanical strength. The manufacturing process ensures void-free construction and optimum interface sealing. This is achieved by bonding the silicone housing directly to the ZnO discs and aluminium end fittings using a special bonding solution.

The surge arresters can be used to protect medium voltage distribution networks and equipment from switching and lightning surge related over-voltages in areas with relatively high iso-keraunic levels. They are for both outdoor and indoor use to protect transformers and cable terminations.

Key Features

- Directly molded housing prevents moisture ingress

- Safe non-shattering short circuit behavior to higher current levels

- Type Tests are independently verified in accordance with IEC60099-4, Ed 3.0 (2014)

- Cage design

- Alternating sheds for best pollution flash over resistance

- Hydrophobic silicone housing for outdoor use

- Excellent operating performance & long service life

Distribution Surge Arrester

Improving Grid Reliability

TE's Range of Surge Arresters

Frequently Asked Questions

Question: What are TE's Bowthorpe Distribution Surge Arresters designed and tested to?

Answer: Our Distribution Surge Arrester is an optimized zinc oxide gapless surge arrester designed and tested to the latest revision of the IEC 60099-4, Ed 3.0 standard (2014). This surge arrester is for rated voltage (Ur- kV) applications up to 36 kV.

Question: Where can the Distribution Surge Arresters be used and what are the typical applications?

Answer: Our Distribution Surge Arrester can be used in the overvoltage protection of medium voltage networks up to 40 kV. Typical overvoltages are primarily due to either lightning or switching on the network. While our Distribution Surge Arresters can be used internally or externally. Typical applications include pole-mounted transformers, overhead line to cable junctures on the medium voltage network, or in areas adjacent to expensive assets that may need to be protected from overvoltages and insulation damage.

Question: What are the main features and benefits of the Distribution Surge Arresters?

Answer:

- Design is based on cage construction with ZnO varistor blocks, Fiber Reinforced Polymer (FRP) rods, and silicone rubber housing.

- The development includes innovative disconnector design which facilitates the ease at which it can be shipped & stored compared to many other disconnectors in the marketplace.

- Directly molded housing prevents moisture ingress and reduces the risk of premature failure leading to longer service life and reduced maintenance costs.

- Safe failure mode during short circuit test. Safety is paramount with a safe failure mode. Our goal is to ensure safety to human life.

- Excellent hydrophobic silicone housing expertly designed for polluted environments. This ensures excellent pollution handling characteristics minimizing aging effects. It can be used in industrial, coastal, or desert regions with long service life.

- Independent laboratory-verified Product Type Tests completed in an EU lab in accordance with IEC60099-4, Ed 3.0 (2014) - DH Classification

Question: How do I select the correct Distribution Surge Arrester for a specific application or customer specification?

Answer: The Distribution Surge Arrester's selection should always start with customer arrester specification. You can contact us to support product selection. Specific network/system parameters are required to ensure that the product selected is optimized to provide the necessary overvoltage protection and minimize the risk of a network outage. System Parameters include:

- System operating voltage

- System grounding, solid, resistance grounded, isolated, etc

- Temporary Over Voltage (TOV) levels or earth fault factor

- Earth fault conditions, max earth fault voltage, and duration or earth fault factor, and duration.

- Basic Insulation Level (BIL) of the equipment being protected

- Connection of arrester, i.e. phase to earth

- Pollution level in the area

- How to connect the line and earth (accessory selection)

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Shed Profile Alternating

-

Core Type Cage

-

Designation Class DH

Electrical Characteristics

-

Steep Lightning Residual Voltage – 1/20µs @ 10kA (kV) 15.7 | 20.9 | 31.3 | 36.6 | 41.8 | 52.2 | 62.8 | 67.9 | 73.2 | 78.4 | 83.7 | 88.8 | 94.1 | 104.6 | 125.5

-

Discharge Current (Nominal) (kA) 10

-

Impulse Voltage 1.2/50µs (Positive) (kV) 174 | 185 | 203 | 230 | 243

-

Residual Voltage (Nominal Current) (kV) 13.7 | 18.3 | 27.4 | 32 | 36.6 | 45.7 | 54.9 | 59.4 | 64 | 68.6 | 73.2 | 77.7 | 82.3 | 91.5 | 109.8

-

Short Circuit Current (kA) 20

-

Continuous Operating Voltage (Uc) (kV) 2.8 | 3.6 | 4.8 | 7.2 | 8.4 | 9.6 | 12 | 14.4 | 15.6 | 16.8 | 18 | 19.2 | 20.4 | 21.6 | 24 | 28.8

-

Qrs (C) .4

-

Voltage Rating (Ur) (kV) 3.5 | 4.5 | 6 | 9 | 10.5 | 12 | 15 | 18 | 19.5 | 21 | 22.5 | 24 | 25.5 | 27 | 30 | 36

Body Features

-

Primary Product Color Gray

-

Product Weight (kg) 1.3 | 1.8 | 2.3 | 2.6

-

Product Weight (lb) 2.866 | 2.866 | 3.968 | 3.968 | 5.071 | 5.732

-

Product Weight (kg) 1.3 | 1.8 | 2.3 | 2.6

-

Product Weight (kg) 1.3 | 1.8 | 2.3 | 2.6

-

Product Weight (lb) 2.866 | 2.866 | 3.968 | 3.968 | 5.071 | 5.732

-

Product Weight (kg) 1.3 | 1.8 | 2.3 | 2.6

Mechanical Attachment

-

Thread Size M12

-

Cantilever Strength -SSL (kN) 225

Dimensions

-

Shed Inside Diameter (mm) 93 | 103

-

Shed Inside Diameter (in) 3.66 | 3.7 | 4.06

-

Shed Outside Diameter (mm) 105 | 120

-

Shed Outside Diameter (in) 4.13 | 4.72

-

Product Height (mm) 160 | 229 | 258 | 298

-

Product Height (in) 6.299 | 6.299 | 9.016 | 9.016 | 10.157 | 10.157 | 11.732

-

Creepage Distance (mm) 405 | 697 | 817 | 945 | 1128

-

Creepage Distance (in) 10.2 | 15.88 | 15.9 | 27.3 | 27.33 | 32 | 37.06 | 44.24

Usage Conditions

-

Power Frequency Withstand (Wet) (kV) 46 | 72 | 87 | 98 | 103

Operation/Application

-

Power Component Application Type Distribution

Industry Standards

-

BIL Rating (kV) 174 | 185 | 203 | 230 | 243

Product Availability

-

Product Availability Worldwide

Packaging Features

-

Packaging Quantity 1 | 3

Reference Number

-

TE Internal Number CAT-DOV

Datasheets & Catalog Pages

- TE'S DOV MEDIUM VOLTAGE SURGE ARRESTER pdf English

- DOV MEDIUM VOLTAGE SURGE ARRESTER pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details