The Aerospace & Defense industries have always been the main drivers for RFI/EMI shielding design and products. Achieving EMC (electromagnetic compatibility) in this sector is safety critical, whereas in everyday life it can just be a frustrating nuisance. RFI/EMI shielding gaskets and components provide exceptional EMC shielding solutions to address regulatory compliance and design challenges aerospace engineers face to drive performance needs.

Aircraft can get struck by lightning with regular occurrence which will cause an electromagnetic pulse or EMP. EMP will have a devastating effect on electronic circuitry, so it is important that the aircraft has a path for the lightning to continue without causing damage. Space is another matter; satellites are in a very hostile electromagnetic environment with solar flares that can emit a coronal mass ejection. We are protected on earth by the magnetosphere, but satellites don’t have that advantage, so shielding is paramount to ensure the safety of the satellite and its systems.

Greater integration of electronics means electromagnetic compatibility between systems is of upmost importance to ensure they work in harmony and not interfere with each other. Aircrafts are more fly-by-wire than mechanical systems, with complex software operating computerized systems. Sensors measuring the aircraft environment, flight data etc. all need to communicate with each other, operate independently and provide back up for system failure or malfunction.

Electronics engineers are very familiar with this and will consider in their design good board layout, filtering, grounding, signal integrity etc. to try resolving EMI at its source. However, shielding of the enclosure is just as important and solves the problem of radiated emissions and susceptibility. Mating surfaces on an enclosure can look very flat and you think there is full metal to metal contact but, in a mass production process nothing can be that flat and gaps will exist. These gaps are slots and can become radiating antennas. This joint unevenness can be addressed by using an electrical gasket and adding more fixings to get good contact between the mating surfaces.

RFI/EMI shielding is a mechanical fix for an electrical problem and the enclosure design engineer should be aware of the types of gaskets available and their different attributes and ensure there is enough land area on the enclosure seams, doors etc. to fit the gasket. In Aerospace, weight and size of equipment and systems is important so miniaturization where possible is used. This means that the shielding options available to the design engineers must also be small and offer good shielding. Electrically conductive elastomers are the best option for Aerospace as the material can be molded, extruded or fabricated into very small components or deposited directly to hardware. Many electrically conductive fillers are available to suit shielding requirements and a fluorosilicone base meets the needs of resistance to fuel oils etc.

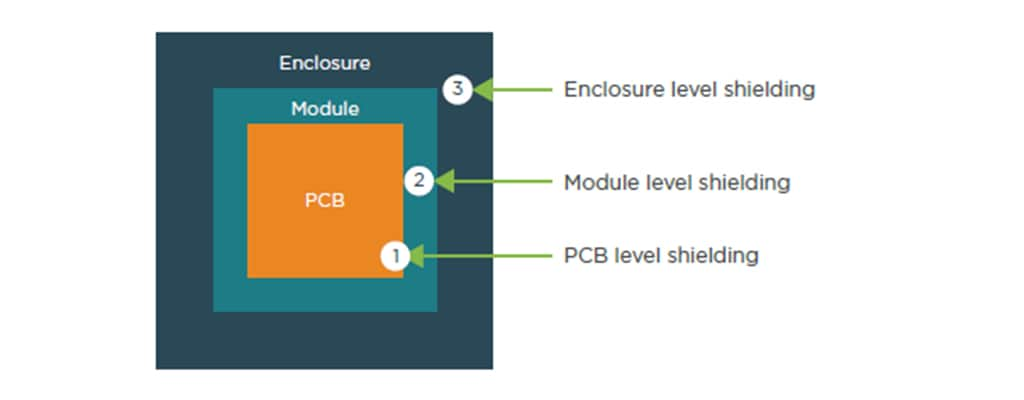

Where is EMI shielding used?

EMI shielding gaskets are applied at the seams of an enclosure to establish a low resistance conductive path to block radiated emissions into and out of the enclosure.

- Conductive gaskets/windows/vents at enclosure assembly level

- Conductive gaskets for module assembly

- Conductive gasket at board level cans at PCB level

EMI Shielding Solutions Benefits

Ensuring Safety and Reliability

Aircraft systems rely heavily on accurate data transmission and communication. EMI can disrupt these signals, leading to potential malfunctions in critical systems such as navigation, communication, and flight control. Effective EMI shielding helps prevent these disruptions, ensuring the safety and reliability of the aircraft.

Compliance with Standards

The aerospace industry is governed by stringent standards and regulations, such as MIL-STD-461, which set limits on electromagnetic emissions and susceptibility. EMI shielding is essential to meet these standards and ensure that all electronic systems operate within safe parameters.

Protecting Sensitive Equipment

Modern aircraft are equipped with numerous electronic devices that are sensitive to electromagnetic interference. Without proper shielding, EMI can cause critical damage to avionics equipment, leading to disruptions or failures in navigation and communication systems. Shielding materials protect these sensitive components from external electromagnetic fields.

Enhancing Performance

Effective EMI shielding not only reduces emissions but also improves the susceptibility performance of electronic systems. This means that the systems are less likely to be affected by external electromagnetic fields, leading to more stable and reliable operation.

Supporting Advanced Technologies

As wireless technology and device signal sensitivity continue to advance, the need for effective EMI shielding becomes even more important. Shielding helps maintain the functionality and safety of avionic equipment, supporting the integration of new technologies in commercial aircraft.

Preventing Catastrophic Outcomes

In the high-stakes environment of aerospace, even minor disruptions can lead to significant consequences. Effective EMI shielding ensures that each component functions without interference

EMI Shieding for Aerospace, Defense and Marine Application

Aerospace Applications

- Avionics Systems: EMI shielding materials, such as conductive elastomers is used to protect avionics systems from interference, ensuring accurate navigation, communication, and control.

- Satellite Systems: Lightweight EMI shielding materials are crucial for satellite systems to reduce weight and protect sensitive electronics from space radiation and electromagnetic interference.

- Unmanned Aerial Vehicles (UAVs): EMI shielding gaskets and vents are used in UAVs to protect control systems and communication equipment, enhancing operational reliability and performance.

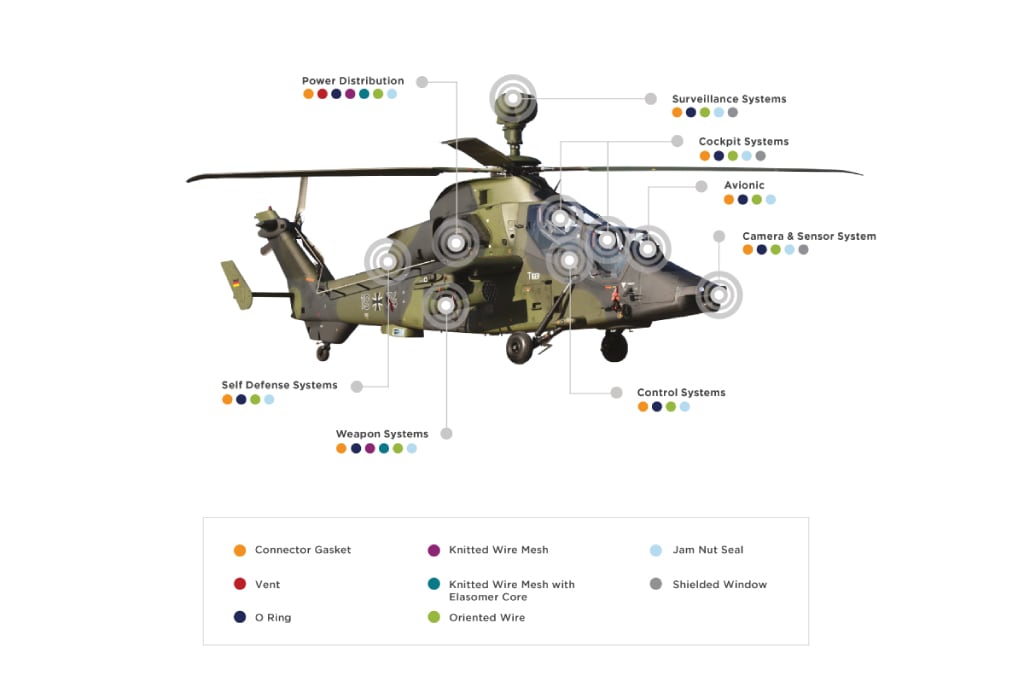

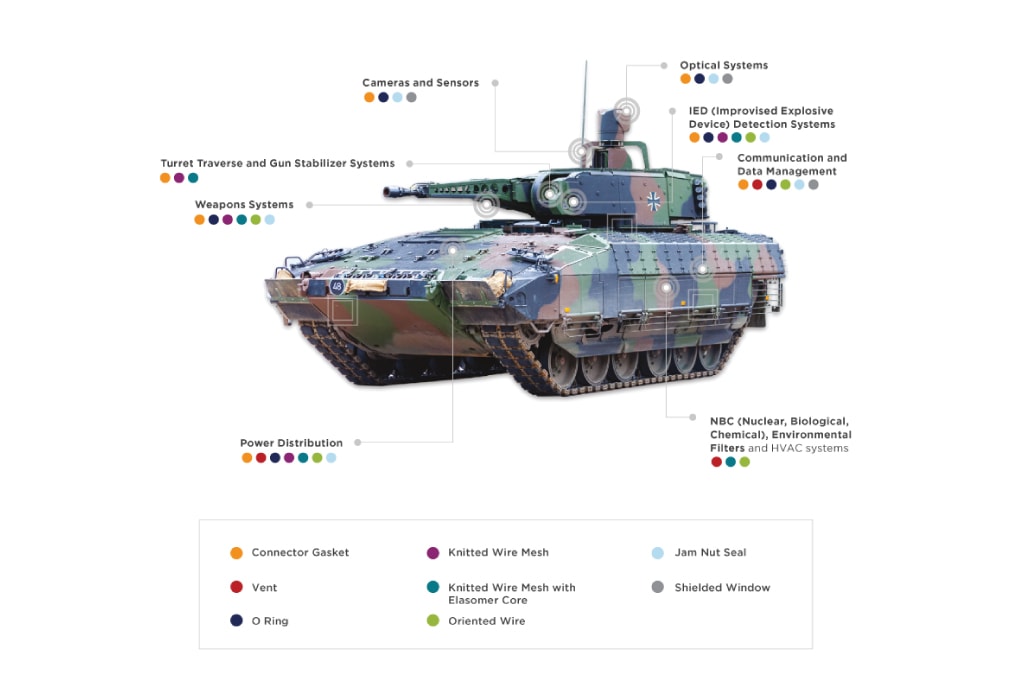

Defence Applications

- Military Ground Vehicles: EMI shielding materials, such as knitted wire mesh and conductive adhesives, are used in military ground vehicles to protect electronic control units and communication systems from interference, ensuring mission-critical operations

- Radar Systems: Shielding solutions provide enhanced EMI performance for radar systems, ensuring clear signal reception and transmission

- Missile Systems: EMI shielding is essential in missile systems to protect guidance and control electronics from interference, ensuring accurate targeting and operation.

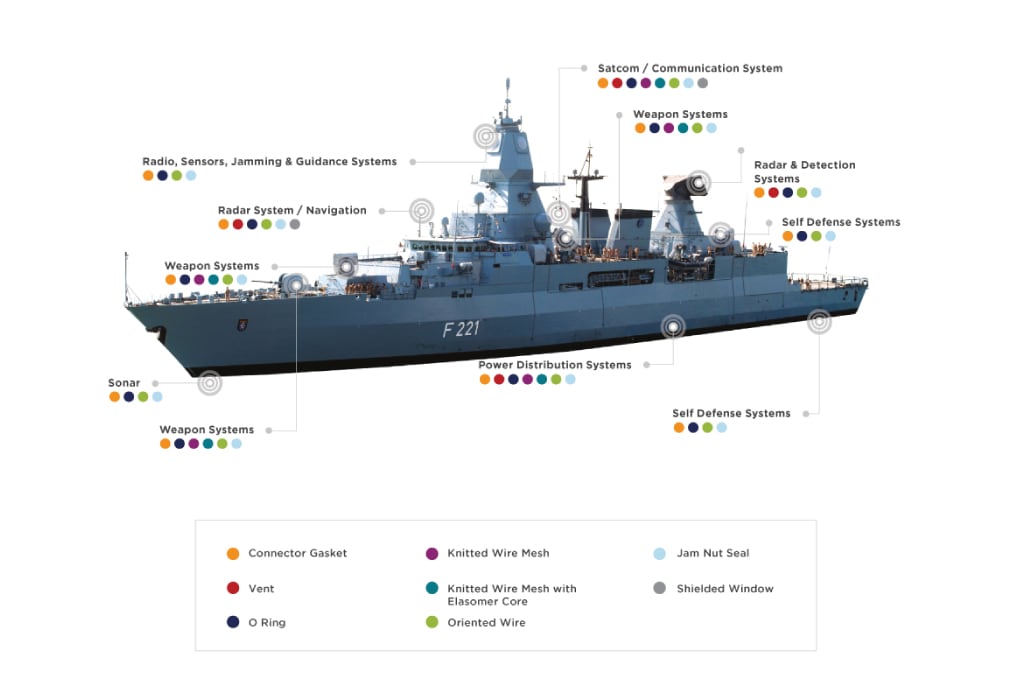

Marine Applications

- Naval Shipboard Systems: EMI shielding materials are used in naval ships to protect communication and navigation systems from interference, ensuring reliable operation in harsh marine environments.

- Submarine Electronics: Conductive elastomers and shielding gaskets are used in submarines to protect sensitive electronic systems from electromagnetic interference, ensuring stealth and operational effectiveness.

- Marine Radar and Sonar: EMI shielding solutions are applied to marine radar and sonar systems to prevent interference, ensuring accurate detection and navigation.

Product Category

EMI Shielding

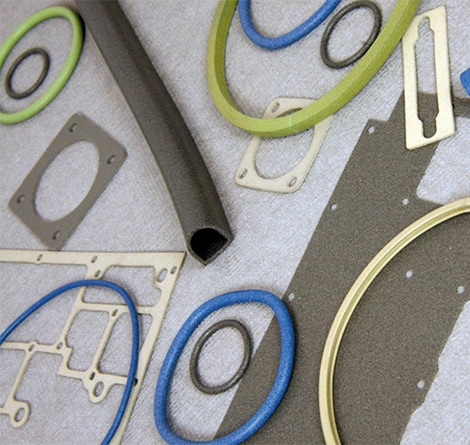

RFI/EMI shielding materials and components provide exceptional EMC shielding solutions to address regulatory compliance and performance needs. Our shielding solutions include electrically conductive elastomers, gaskets, knitted wire mesh, oriented wire, EMI shielding ventilation panels, shielded window, cable shielding and shielding components.

Explore Now