Vacuum Chamber

TE provides the reliable components you need to help prevent contaminants entering the system and reduce leakage.

Providing in Sealed Connectivity

Vacuum chambers are used extensively in the semiconductor manufacturing process, including in the critical deposition and etching phases. Newer processes such as atomic layer deposition (ALD) require even higher vacuum levels than chemical vapor deposition (CVD) or physical vapor deposition (PVD) techniques. However, a vacuum chamber is notoriously difficult to build, operate, and maintain at a high-performing level.

In order to not contaminate the process, it is critical for components and materials used in the vacuum chamber to be low outgassing. Electrical connections going in and out of the chamber must be sealed properly to prevent vacuum loss. As process needs increase and vacuum requirements rise, OEMs constantly control for all of these factors, which is another reason that so many have leaned into the smart manufacturing capabilities enabled by Industry 4.0.

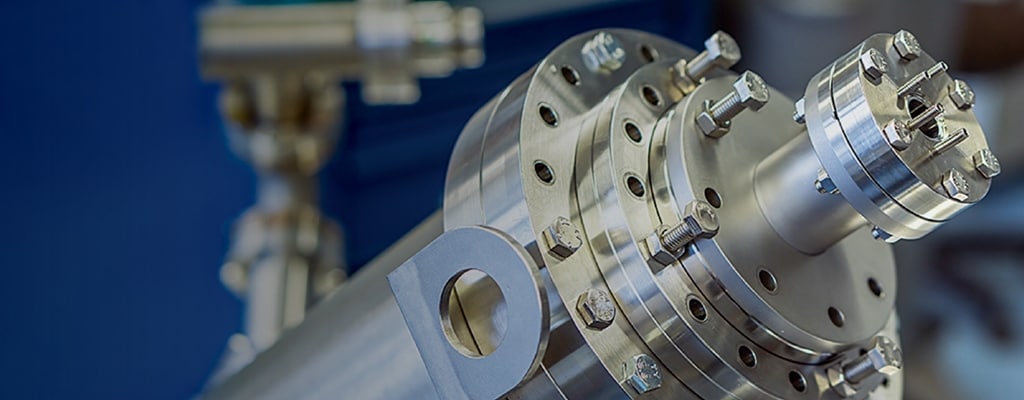

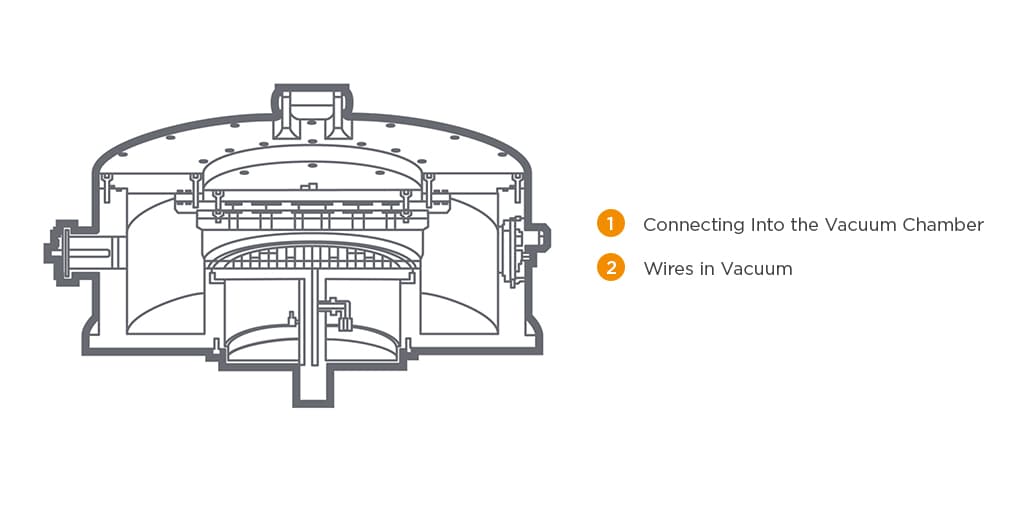

Connecting Into the Vacuum Chamber

Get reliable electrical connections into the chamber while saving vacuum volume and reducing leakage.

Wires in Vacuum

Significantly reduce the chance of contaminating the vacuum and semiconductor wafers with low outgassing wires.