Machine Wiring

To help ensure product accuracy, our teams can meet your needs, provide tailored build-to-print services, and inspect every component and cable before it ships. Plus, TE’s thorough cable identification system provides more reliable, field-tested labels that meet your requirements for traceability.

We Are Here to Meet Your Exacting Requirements

Used to distribute power, data, and signal within semiconductor manufacturing equipment, machine wiring is needed to connect controllers, sensors, actuators, motors, plasma generators, and other devices. In essence, the machine wiring is the nervous system that connects all the parts of the machine together so they are powered and can communicate with each other and function properly. Because of this, quality control and traceability are of utmost importance in machine wiring.

Some semiconductor manufacturing equipment requires that special materials be used in machine wiring to ensure cleanliness or to prevent outgassing. Regardless of the system, if needed, cable assemblies and cordsets go through specific testing, labeling, and packaging procedures to fit the exacting needs of each OEM.

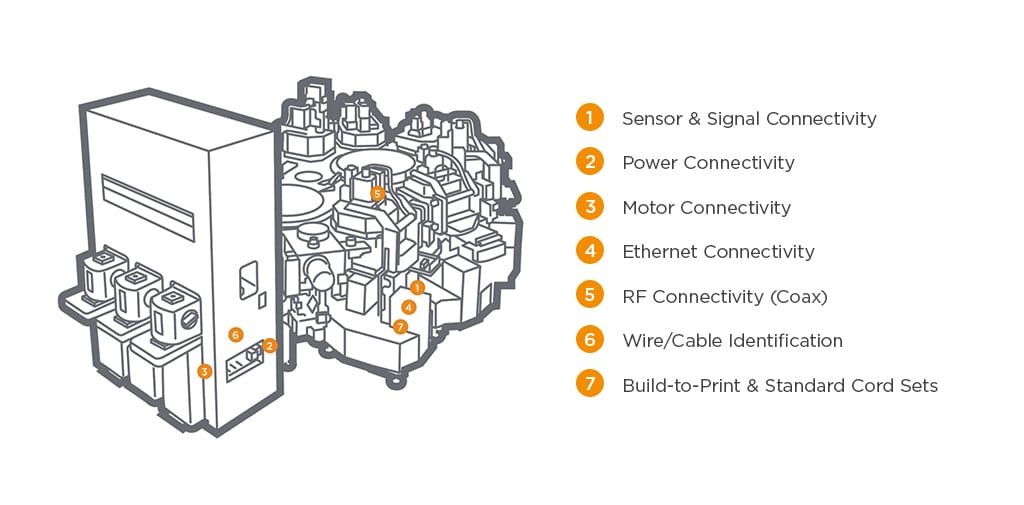

Sensor & Signal Connectivity

Look to TE’s highly reliable connectivity that allows for the high cabling density you need.

Power Connectivity

Highly reliable connectivity that allows for a variety of power levels in your machine wiring application.

Motor Connectivity

Find a wide portfolio of connectors specifically designed for motor applications.

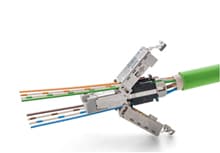

Ethernet Connectivity

Industrial grade Ethernet connectors increase reliability and reduce package loss.

RF Connectivity (Coax)

Get rugged solutions to reliably transmit high frequency or sensitive analog signals.

Wire & Cable Identification

For identification that is durable, readable and traceable for decades, turn to TE’s ID solutions.

Build-to-Print & Standard Cord Sets

Get highly reliable and traceable cord sets for signal and data connectivity over the lifetime of the machine.