Using Microfluidic Chips for 3D Cell Culture

Cell culture using microfluidic “lab on a chip” technology offers many advantages over conventional 2D cell culture in Petri dishes or transwells and is being used in a variety of diagnostics, immunology, cancer research, drug discovery, drug screening and stem cell biology applications. Cell culture can start from something as small as a single cell to fully intact tissue samples. Microfluidics opens new possibilities with cell culture as microfluidic cultures allow the control of the physical and mechanical microenvironment. This leads to a more biomimetic, and therefore realistic results compared to standard cell culture procedures. Moreover, microfluidics allow automation of long term cell culture assays, requiring little sample handling compared to conventional cell cultures. The high degree of automation enhances reproducibility and high-throughput and makes it excellent for applications that require high sensitivity diagnosis. Switching to this technology may make sense if your current cell culture process:

- Requires a biomimetic cell behavior

- Requires a frequent handling and monitoring

- Has long processing times

- Requires relatively small amounts of culture medium

- Uses a substantial amount of costly reagents

Microfluidic Cell Culture Gives You More Control

Two words sum up the advantages microfluidics offers over traditional cell culture techniques: control and consistency. One of the primary challenges of traditional cell culture techniques is maintaining control over the microenvironment. Doing this requires a lot of monitoring and staff time that could be spent focusing on other productive activities. Microfluidics offers a higher degree of fluid control and automation than traditional cell culture techniques. With appropriately sized channels and chambers that can accommodate biological cells and tissues, microfluidic chips give you precise control over the chemical and physical microenvironment including:

- Convection

- Diffusion

- Reaction

- Flow rate

- Mechanical stimulation

- Electrical stimulation and sensing

- Cell matrix

- pH levels

- Temperature

- Monitoring

- Cell placement

- Cell numbers

- Dose delivery to cells

- Density

Having control over the cellular and biochemical microenvironment is extremely important, especially for stem cell applications. When cells consume culture medium and metabolize, nutrients and oxygen can be monitored and replenished continuously using continuous perfusion systems, and waste can be carried away via fluid flow. Microfluidics can mick the microenvironmental conditions of the desired case study, leading to a more realistic and reliable models and results.

See how the TE IVD Solutions team can scale your cell culture efforts.

Inertia and Cost Concerns

Obviously, cell culture using microfluidic technology is not without some drawbacks, many of which are being addressed in various ways. The primary limitations for adopting microfluidics for cell culture applications are inertia and money. Conventional 2D cell culture methods have been around for more than 100 years and it can be a challenge to get people to adopt new technology, especially one that is more complex to learn initially. Regarding money, while manufacturing microfluidic chips can be relatively inexpensive once designed, switching from a simple 2D cell culture methodology to a more complex 3D microfluidic technology can be costly to set up. In the long run those costs are offset because once designed and implemented, a microfluidic process saves labor time, is scalable and consistent.

While the presence of shear stress on cells can be a key parameter to generate certain microenvironmental conditions (endothelial cells), it could also be an issue, that may be overcome by reducing flow rates, altering channel depths or geometries, incorporating microwells and other techniques. While the technology associated with microfluidic channels, pumps and valves, is always improving, microfluidic chips may not be a good fit for some applications including those with large tissue explants.

Materials Used in Microfluidic Cell Culture

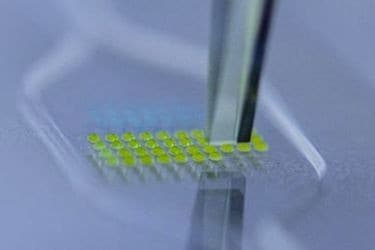

Most cell culture chips and micromechanical valves are made from PDMS which is easy to fabricate and exhibits excellent biocompatibility and transparency characteristics (good for fluorescence detection). Other thermoplastic polymers offer promise for specific microfluidic cell culture use cases:

- Polystyrene (PS)

- Polycarbonate (PC)

- Cyclo-olefin polymers and copolymers (COP)

- Polymethyl methacrylate (PCCA)

All of these have various pluses and minuses related to fabrication, oxygen permeability, biological inertness, ease of bonding, autofluorescence and optical clarity. One drawback of PDMS is that is has a tendency to absorb small molecules and thus can be challenging for studying longer term interactions.

Applying Microfluidics in 3D Cell Culture

Cell culture has traditionally been done in two-dimensional format using flat plastic dishes. This method is inexpensive and simple to understand. However, conducting cell culture in a 2D environment makes it difficult to get a true understanding of how the cells interact with one another and the surrounding 3D extracellular matrix (ECM). When used exclusively for studies, 2D cell cultures may result in misleading data.

Microfluidics supports 2D and 3D environments but the most compelling argument for investing in a microfluidic solution is to replicate 3D “in vivo” cell activity. Microfluidic cartridges work well in a 3D construct since real 3D networks and scaffolds can be created and inserted to regulate fluid flow.

Organ-on-a-Chip Applications

While microfluidics applications for cell culture is becoming more widely adopted in research settings, commercial applications are emerging. One exciting applications is generally referred to as “organ on a chip” and is used to study lung, heart, liver, kidney, gut and other cellular interactions. This field holds commercial promise because of the contributions that it may make to pre-clinical drug research, clinical diagnosis, personalized treatment, regenerative medicine, identifying disease biomarkers and more.

From Evolution to Revolution

New technological advances are helping to propel microfluidic chip-based cell culture from the research lab into commercial applications, with wide reaching implications for disease diagnosis, treatment and drug screening applications. 3D microfluidic cell culture platforms offer lower reagent and medium costs plus advanced control of microenvironment. What’s more, improvements in automation - including the addition of pneumatic pumps and valves – are opening new applications for the technology while making it more automated. The technology offers much promise for those willing to embrace it.

Learn About TE’s Design and Development Expertise