Manage Crimp Quality with Vision Inspection

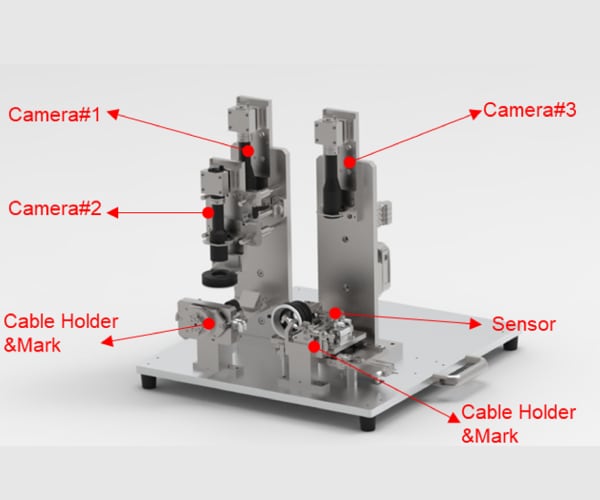

Our new data connectivity inspection machine automatically checks the insertion depth of terminals while detecting concentricity, and shell deformation within data connectivity wire and harness applications.

Features and Benefits

- Quality Management

- High Performance

- Flexible Configuration

- Cost Effective

Applications

in Data Connectivity

- Systems

- Infotainment

- Safety

- In-vehicle networks

Applied Data Connectivity Connector Systems

Compatible with the Multi-Station Processing System (MSPS)

Vision Inspection Machine in MSPS

The vision inspection machine can be added as the sixth station in the Multi-Station Processing System (MSPS) and check the quality of Male & Female terminal:

- Deformation (Male & Female)

- Interference detection (Female)

- Concentricity (Male)

- Depth Measurement (Male & Female)