Modular Hybrid Connector Designs for Zonal Vehicle Architecture

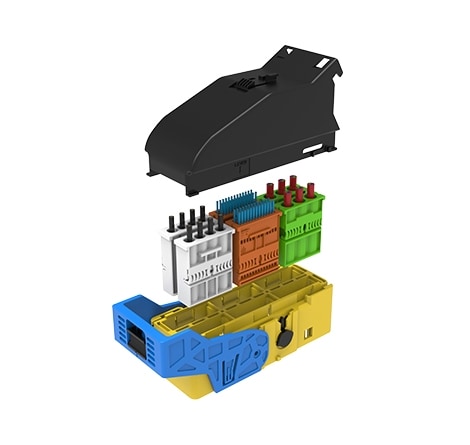

TE Connectivity (TE) offers modular hybrid connector solutions designed for the needs of next-generation E/E architectures. Designed from the start with sustainability and automation in mind, TE’s modularized solutions are smarter and smaller than ever, and better at multitasking, such as transmitting signals and power alongside high-speed data.

Zonal

Addressing the needs of next generation E/E architectures.

Hybrid

Combining signal, power and data connectivity all in one product.

Flexible

Modular, automation-ready and scalable connector configurations.

Paving the way for modular, scalable and flexible vehicle designs, TE Connectivity offers an extensive range of cutting-edge connectivity products and technologies developed for the needs of next-generation E/E architectures. These include modular hybrid connector systems that reduce complexity as well as overall PCB footprint and weight, compared to multiple individual connectors while achieving the same functions. Additionally, these products are engineered and manufactured with high sustainability standards and are automation-ready.

TE Modular Hybrid Connectivity Solutions

| MHS - Modular Hybrid System | NET-AX+ Modular Hybrid Data Connector System |

|

|

MIXED VS. HYBRID VS. MODULAR CONNECTIVITY SOLUTIONS

| MIXED (Signal, Power) |

Mixed connectors are designed to combine multiple Signal and Power terminal sizes within a single connector interface (i.e. 0.50mm, 0.64mm, 1.2mm, 2.8mm, etc.). |

| HYBRID (Signal, Power and Data) |

Hybrid connectors take the concept of mixed connectors further by integrating high-speed Data Connectivity terminals within a single connector. |

| MODULAR (Flexible, Scalable, Automation-Ready & Miniaturized) |

Modular connectors can be customized or adapted by combining different modules or components into a single connector housing leading to maximum flexibility, scalability and time-to-market. |

Benefits

- Flexible and scalable multifunctional configurations for signal, power and data connectivity..

- Consolidation of vehicle functions and connections.

- Smart designs offering less space consumption and weight reduction.

- Readiness for partial and full automated harness production.

- Cost-effective solutions based on standardized modules, reducing lead times and inventory.

- Emission-reduced and eco-friendly solutions using sustainable resins.

- Modular and scalable connectors matching customer connection needs.

- Qualified TE low voltage terminal systems.

- Wire-to-board and wire-to-wire applications.

Applications

Zonal Control Units :

- Wire-to-board applications

- Wire-to-wire applications (inline harnesses)

High-Performance Computers/Control Units:

- Autonomous Driving /Advanced Driver Assistance (ADAS)

- Infotainment

- LiDAR/ Radar