Connectivity Solutions for Next Generation E/E Zonal Architectures

The increase in electronic content is driving the need for reduced scale and complexity of the physical wiring network within vehicles. This is driving a shift from fragmented, functionally oriented distributed architectures to more centralized and simplified zonal architectures. To meet this need, TE Connectivity has designed and developed a broad range of hybrid, mixed and modular connector solutions based on established OEM-released interfaces supporting both signal, power, and different types of data connectivity to support a large range of automotive applications.

FLEX

Modular, scalable, automation-ready & miniaturized.

ZONAL

Reduced E/E architecture complexity, space, weight, and cost.

3-in-1

Robust solutions integrating data, signal, and power into one single connector.

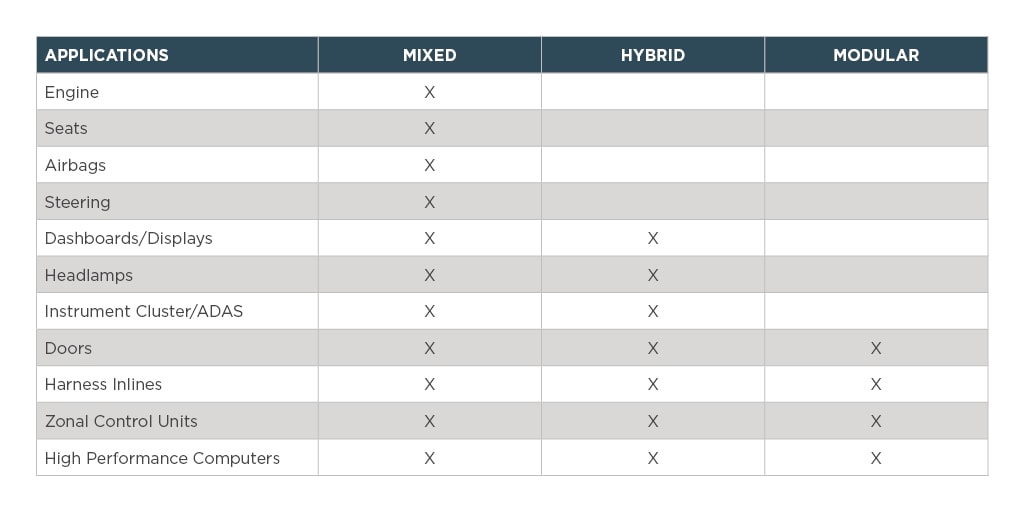

MIXED VS. HYBRID VS. MODULAR CONNECTIVITY SOLUTIONS

| MIXED (Signal, Power) |

Mixed connectors are designed to combine multiple Signal and Power terminal sizes within a single connector interface (i.e. 0.50mm, 0.64mm, 1.2mm, 2.8mm, etc.). |

| HYBRID (Signal, Power and Data) |

Hybrid connectors take the concept of mixed connectors further by integrating high-speed Data Connectivity terminals within a single connector. |

| MODULAR (Flexible, Scalable, Automation-Ready & Miniaturized) |

Modular connectors can be customized or adapted by combining different modules or components into a single connector housing leading to maximum flexibility, scalability and time-to-market. |

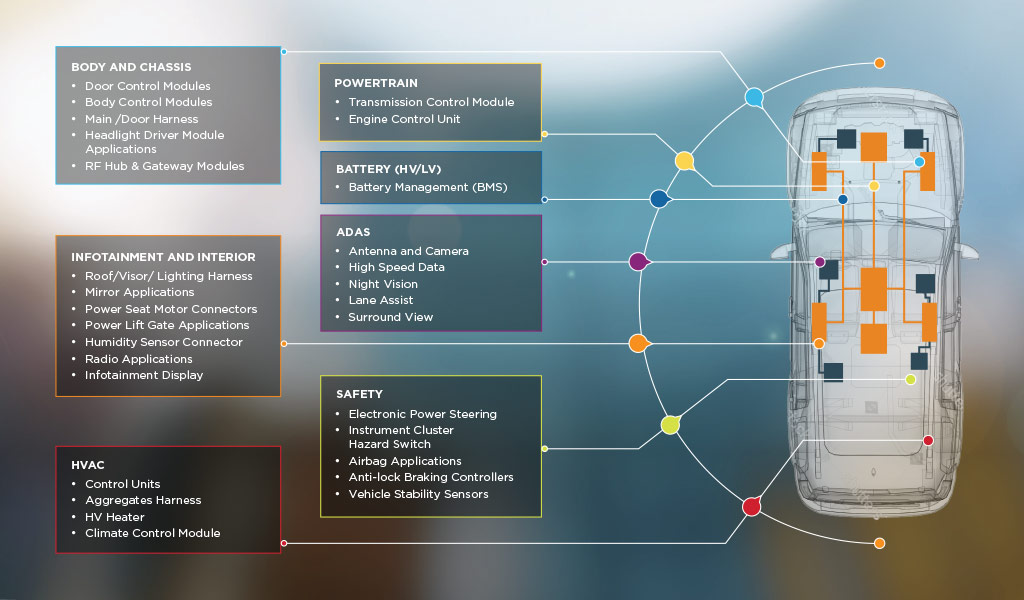

Next Generation Zonal Architecture Solutions from TE Connectivity

TE Connectivity (TE) offers an extensive portfolio of hybrid, modular and mixed solutions offering multiple combinations of signal, power and data connectivity that meet the needs of the new generation of zonal and centralized control units. Based on established OEM approved interfaces and addressing the needs of a wide range of automotive applications, we offer assembly-and space-optimized connectivity solutions with high modularity for accelerated time-to-market, automation, and scalability.

APPLICATION REQUIREMENTS

- Simplification - consolidation of vehicle functions reducing the number of decentralized ECUs.

- High port densities on High Performance Computers (HPCs) and Zone Controllers with multiple hybrid/mixed data, signal and power connector configurations in one connector assembly.

- Modularity, scalability, flexibility, and interchangeability.

- Support robust high-speed data transmission.

- Space saving / miniaturization and weight reduction.

- Fully automated harness production and vehicle automation capable.

- Cost-effective platform.

- Low carbon content and eco-friendly.

BENEFITS

- Assembly, and space-optimized connectivity tailored to customers application needs.

- Patented 2K silicone housing at the junction of doors and vehicle body.

- Fast and secure connection of sub-harnesses.

- Modular and scalable design leading to semi-/automated production of (sub-) harnesses.

- Only one connector to be assembled at the OEM.

- Modularity for accelerated time-to-market, automation, and scalability.

- Reduced mating forces with supported plating technologies.

- Manufactured with sustainable resins, and optimized surface technologies.

- Supply chain resilience.

- Opportunity for greater component standardization.

- Space-saving and weight-reduction compared to multiple single connectors.

Generation Y 68P Sealed Hybrid Inline Connector

- 65% Less Supply Chain Complexity

- Cost-effective

- Ease of Manufacturing and allows for improved packaging and wire routing

- Reduced Footprint

- Automotive grade robustness including male side pin protection plate

- x44 TE Generation Y .64mm Terminal System

- x2 TE Mate-AX Mini Coax Terminal System

- x10 2.8mm Terminal System

- x12 1.5mm Terminal System

Next Generation E/E Portfolio Applications

e

e

e

e

e

e