DIP Sockets For Reliable Connections

SIP (Single In-Line Package) sockets with machined female header, DIP (Dual In-Line Package) sockets and HOLTITE sockets can provide a reliable connection between integrated circuit devices and printed circuit boards. The HOTLITE socket contact is designed as a press-fit solution with the plated through-hole of a printed wiring board. For DIP package components, the HOLTITE socket contacts on reel have disposable terminal carriers that can be peeled away and disposed of after assembly.

Key Benefits

Easy Assembly

- Support quick mating and un-mating

- Enable easy replacement of the IC

Optimized Design

- Minimize the risk of IC overheating during soldering

- Provide improved vibration resistance with multi-contact beam design

Better Durability

- Durability up to 500 cycles with gold plating

- Support flame resistance with UL 94V-0 rating with PPS (polyphenylene sulfide) housing

Broad Portfolios

- Offer various specifications to address customer demands

Target Applications

- Industrial controls

- Intelligent buildings

- Medical devices

- Military

- Other embedded systems

Product Features

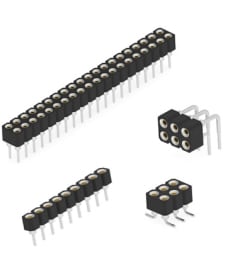

DIP Sockets

- HOLTITE socket (solderless zero profile) is available

- Precision four-finger inner contacts or dual leaf contacts are optional

- Open frame and closed frame housings

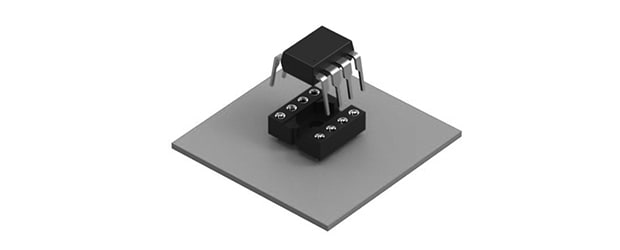

IC-to-Socket-to-Board

Four-Fingered Contacts

Precision machined or stamped four-finger inner contacts with open or closed frame housings facilitate highly reliable DIP sockets.

Dual Leaf Contacts

Dual leaf contacts provide a cost effective solution to the DIP socket design with superior handling characteristics.

-140x140.jpg)

Zero Profile(HOLTITE)

HOLTITE socket contact is designed to be press-fit into the plated-thru hole of a printed wiring board, offering the solderless zero profile by allowing the plated-thru hole to become the component socket. For DIP package components, the HOLTITE socket contacts on reel provide with disposable terminal carriers, which can be peeled away and disposed after assembly.