Product Insight

SMD Advancements

Recent technology improvements in power SMD resistors have resulted in significant performance capability. Newer products deliver three times the power of resistors from just a few years ago, and a similar increase in power-to-size ratio. These advancements have resulted in devices that are smaller, lighter, and more robust in performance.

As with all things in the electronics industry, advancements in design and production are enabling manufacturers to continuously improve their portfolio. Over the past few years, we have seen materials become more efficient, and manufacturing techniques more controllable. From this, we have engineered a portfolio of power resistors – including our surface mount resistors, also known as surface mount devices (SMDs) – to provide more capability than ever before.

Select Power Surface Mount Resistors

Browse by Type and Element

What's the difference between a pre-charge resistor and an in-rush resistor? What about a braking resistor or a crowbar resistor? Which types of resistors offer short-term overload capability and which offer continuous power dissipation? Learn all this and more, in this glossary explaining the technology of our power resistors.

It’s crucial to keep in mind that resistors are simple things, designed for a single function: to convert excess electrical energy into heat, using an electrically resistive material. New materials and techniques are taking this basic idea to the next level.

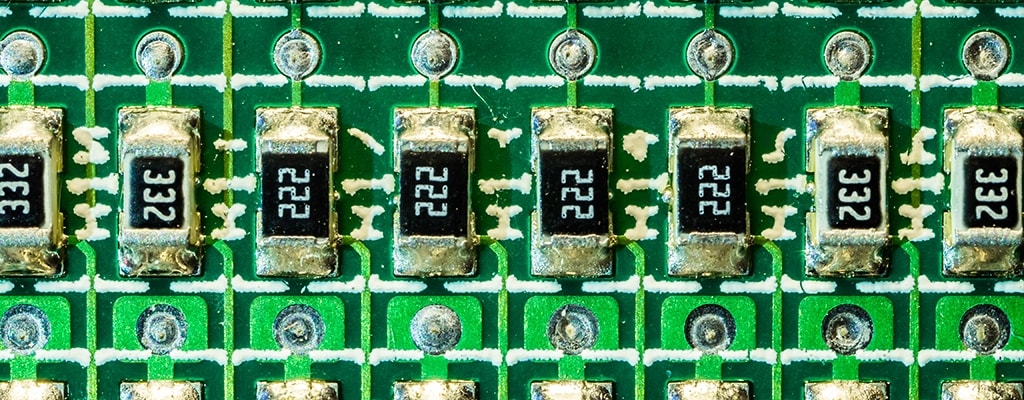

Take for example the CRG series of power resistors, which is designed for surface mounting onto the printed circuit board (PCB). Only a few years ago, these thick-film chip resistors were seen as delivering ground-breaking performance. Today, these are a reliable and popular solution, such as the 2512 package resistor, the largest in the CRG series, which provides a power rating of 1 watt. As good as the performance is, the technology used to manufacture SMD power resistors has been superseded by recent advancements.

Today, newer product families – such as the 3522 series – are built with the latest conductor and substrate materials, resulting in a resistor that can deliver a three-fold increase in power capability, and a similar increase in the power-to-size ratio. Increasing the power-to-size ratio enables you to design more capability onto the PCB and offers more flexibility on board layout.

A power circuit that previously might have required several low-powered resistors can be re-designed using fewer components with a higher power rating. This reduction in component count leads to reduced overall costs and a more efficient supply chain. Alternatively, the greater power-to-size ratio means that the same capabilities require smaller resistors, allowing you to make more efficient use of board space.

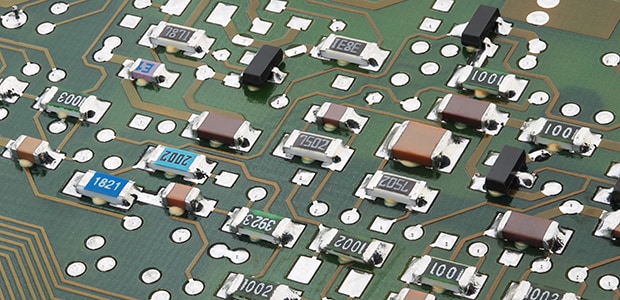

Because the power-to-size ratio compares the performance of the resistor with its physical size, any improvements in this ratio allow you to add more smaller components to the PCB, enabling you to design smaller, lighter, faster, more robust devices that offer more capability. Whether mounted onto PCBs or bolted to a chassis, this new generation of SMD power resistors give you options over using traditional leaded designs, which are bulky and often limit how close they can be installed onto a PCB in relation to other components. This also creates design opportunities over using wirewound resistors, which are mounted away from the PCB.

In choosing SMD power resistors, you get a component that not only offers a much lower profile than leaded resistors, but also one which makes more efficient use of space on the board. As a result, you can design in more capability into the existing space or reduce the size and weight of existing equipment. And because installation uses the same automated process as the other board-mounted components, manufacturers can realize significant cost saving when it comes to assembly.

Surface Mount Resistors in Select Applications

To understand the advantages of using SMD chip resistors, let’s look at some of the technology found in most homes. Vacuum cleaners have become compact yet more powerful as a result of using smaller, lighter, and slimmer SMD power resistors in the design of the motor and power management systems. To find components right for your design, browse our portfolio of surface mount power resistors, like the 3522 series, to learn how these solutions can help improve your design.

After you know what you need, browse our broad portfolio of power resistors to find the right solution for your design. You can also contact our product specialists to learn how we can help you determine your power requirements.

e

e

e

e

e

e

e

e