Trend Insight

‘Sensing’ and ‘Seeing’ What’s Critical in Our Environment

Sensors are a growing part of our connected world and increasingly core to applications throughout our lives. Discover four key design challenges today’s engineers face by downloading the report.

The Design Challenge

Sensors are a growing part of our connected world and increasingly core to applications throughout our lives. As sensors are becoming integrated into a range of products, and as demand skyrockets, design engineers face new challenges in optimizing performance for current and new applications. They often must use sensors to monitor temperature, humidity, position, pressure, and much more.

The Role of Humidity Sensors

Humidity is the amount of water vapor present in the air. While invisible to the human eye, we can feel it. It may even seem hotter than the actual temperature. And for those who have traveled to different regions of the globe — particularly near the equator — the air will feel hot and heavy, giving you that muggy and steam-rolling feeling. The discomfort is not due to the temperature alone but the ‘relative humidity.’ It can be 75° Fahrenheit (or 23°C) with relative humidity at 80%+, and yet we’ll feel like it is 80°F (or 26.6°C) out. Humidity plays an important role in our day-to-day activities. Whether it’s related directly to your personal comfort (keeping food fresh and running the HVAC system in hot weather) or more critical, life-threatening situations such as ensuring a premature baby has the right added humidity for neonatal care and growth. The ability to precisely control our environment is a standard expectation in much of the world today, and simply wouldn’t be possible without sensors.

At TE Connectivity (TE), our humidity and temperature combination sensors offer leading response time, precision in measurement, and sustained performance even when exposed to extreme changes and conditions. In fact, we’ve been at the forefront of pushing advances in sensor technology into digital, wireless, and combination solutions that help make applications smarter and more efficient. Here is a closer look at some of the biggest challenges design engineers face and how the HTU2x humidity and temperature combination sensor from TE has been engineered to deal with these challenges.

Whether sweltering hot, freezing cold, wet or dry, applications require the same system efficiency in all humidity and temperature ranges to achieve the most reliable performance. This means that regardless of the external environmental conditions, the sensor has to always perform at its optimum best. Linear response is key. Regardless of temperature and humidity variations, measurement accuracy and stability must remain the same with a sensor. This is critical in applications where the environment is sensitive to changes such as in industrial and appliance use. As an example, the sensor should be designed to offer precise measurement by giving a linear response and the lowest hysteresis. A good example is for HVAC applications, where the system is regulating the ambient temperature and humidity for your comfort zone, whether it’s a hot summer day or rainy winter outside. Humidity sensors go through major relative humidity variation phases, season over season and need to keep their response linear. The system has to adapt to the varying seasons that could impact the comfort in your home or office. The linear response curve of HTU2x will allow the HVAC system to keep the same performance regardless of the conditions.

Some applications require that you have designed in the ability to sense all environmental variations and can react quickly, offering best-in-class overall system performance. Fast response time is an industry must-have. It’s simply not enough to have accurate measurements – sensors need to detect environmental changes quickly and trigger action in the application to maintain desired levels. As an example, weather balloons are the workhorses of modern meteorological forecasts. It’s nearly impossible to predict the weather without knowing the conditions of the upper atmosphere. It may be sunny and quiet at sea level, but at 18,000 feet (5,486 meters), a weak storm system could soon turn into something more dangerous. By sending up regular squadrons of balloons to measure the conditions of the upper atmosphere, meteorologists can keep tabs on brewing storms.

After exposure to extreme conditions, the system performance cannot be compromised. Low hysteresis is a key capability. Even after important condensation events, the sensor needs to maintain precise measurement performance. As an example, an appliance drying cycle will automatically stop when humidity is back to its original point. The low hysteresis will allow it to stop the drying cycle on time when the ‘inside’ content is dry without damaging it. In another example of an HVAC system, even after being exposed to an extreme high humidity rate for a long period during the fall and winter seasons, the HVAC system will perform exactly the same in hot summers.

The HTU sensor — thanks to its fast response time — will detect accurately the relative humidity in different atmospheric layers. This helps predict these weather changes, and avoid any alarming situations such as sending false information when it crosses a cloud. Another relevant example is with appliance applications. When you open the refrigerator door in the summer, hot air enters the fridge causing condensation and increasing relative humidity, resulting in frost or freezer burns on the inside wall. TE’s humidity die structure enables industry-leading response times in 2 sec. The fast response time permits the system to react immediately in real-time to avoid such a scenario. In other words, it prevents the freeze formation, which means the defrost cycle will be shorter for better energy efficiency.

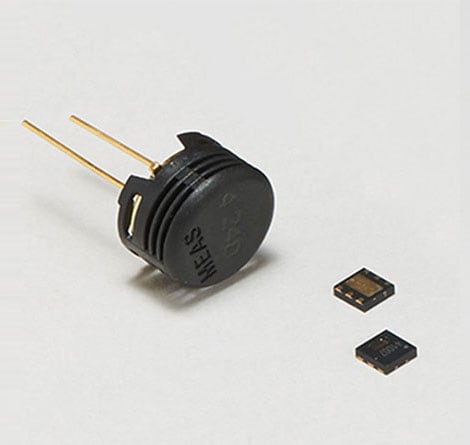

Nowadays OEMs innovate their offerings with smart solutions like sensors, yet they need to integrate them into their manufacturing process without negative consequences. TE’s HTU sensor allows integration in the standardized package fully calibrated, and integration on a printed circuit board without any constraints. If you’re looking to upgrade or to upgrade the next generation of your system to a smarter application without drastically changing your assembly process, try out TE’s HTU sensor, which is compatible to standard SMD assembly processes.

The World of Sensors — Meeting Demanding Challenges

At TE Connectivity, we believe that improvements in technology will help shape the future of energy conservation. And our humidity and temperature combination sensors (the HTU20/HTU21) are playing a role. The right sensor solution can dramatically optimize your applications. With 20+ years of experience, we provide humidity and temperature combination sensors that offer leading response time, precision in measurement, and sustained performance even when exposed to extreme changes and conditions.