Building the Future of Construction Equipment with TE Connectivity

Your vision + Our engineering = Solutions tailored to your connectivity challenge in your heavy duty equipment designs.

The global construction equipment market transformation is accelerating. Zero-emission mandates, EPA Tier 4 or EU Stage V compliance, and digital fleet management aren't future trends – they are the reality reshaping your design priorities. Your customers demand excavators and wheel loaders that deliver automotive-grade connectivity while surviving quarry dust, hydraulic shocks, and temperature extremes that destroy consumer electronics in hours.

Connectivity is Key!

When 430 kW e-axles power through 12-hour shifts and 20-minute megawatt charging keeps fleets moving, connector failures don’t just cause downtime - they halt entire projects. Your vehicle networks, predictive maintenance, and ADAS safety systems demand SAE J2030-compliant connections that preserve signal integrity under years of vibration, dust, and heat, keeping machines productive and profitable.

That is where TE comes in.

Our heavy-duty connectivity solutions deliver proven performance across major construction equipment systems. Our rugged connectors provide reliability, durability, and smart machine integration in harsh environments.

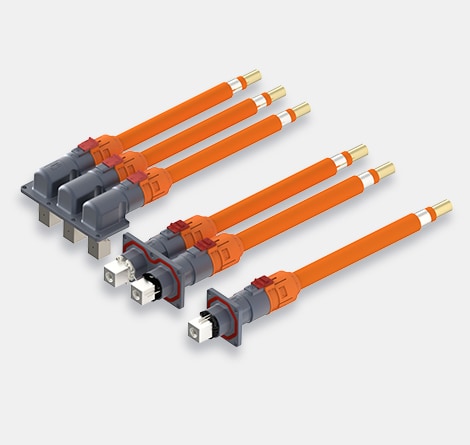

Battery & Charging Systems

Zero-emission mandates drive electric excavator adoption but charging reliability in field conditions determines success. When 500kWh battery packs fail to charge on remote sites, expensive machines become scrap. You need high-current connectors and charging inlets handling 350A+ while resisting corrosion and thermal cycling.

Chassis & Cabin

Heavy equipment like wheel loaders, dump trucks, and excavators operate in muddy, dusty, and uneven job sites. Protecting cabin and chassis electronics from vibration, moisture, and debris is critical. You require sealed and robust connectors that provide reliable vehicle network connectivity and uninterrupted machine operation.

Machine Motion & Control Systems

Hydraulic failures in cranes or aerial lifts aren't just equipment damage – they are potential fatalities. Safety standards tighten while operators demand precision control. Boom cylinders and outriggers experience shock loads that shatter electronics yet must provide millimeter control. Our sealed connectors provide safety-critical reliability through impacts and pressure spikes.

Power Distribution & Energy Management

Hydraulic excavators and mining trucks face load spikes that destroy standard electronics. With EU Stage V regulations driving energy efficiency and 24/7 cycles demanding reliability, one inverter failure can lead to costly downtime and reputational damage. You are looking for heavy duty connectors to optimize load management and extend battery life cycles.

Smart & Connected Construction Machinery

Digitalization drives demand for ADAS, cameras, lidar/radar, and telematics in construction machinery. You face the challenge of integrating infotainment and driver-assist systems that boost safety, productivity, and connectivity and that won’t stop working even in harsh conditions.

Transmission & Powertrain Connections

When excavators and bulldozers endure 12-hour shifts in dusty quarries, transmission failures halt entire projects. EPA Tier 5 regulations force powertrain redesigns integrating e-motors with engines. You need high-voltage connectors and through-wall solutions that withstand 3G+ vibrations while managing 800V+ systems. Our connector solutions maintain power integrity through -40°C to +125°C swings.

Accessories & Auxiliary Systems

Supporting functions like pumps, compressors, and ePTOs require robust connectors and controls to help ensure efficiency. Thermal management components are increasingly vital as electrified systems produce new heat loads, demanding smarter cooling solutions. Our sealed connectors support auxiliary systems to maintain peak performance through temperature cycling and contamination.

Tooling

From prototyping and wire harness assembly to field repairs and high-volume production, our application tooling solutions ensure reliable crimp connections for the construction equipment industry.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e