High Performance Design

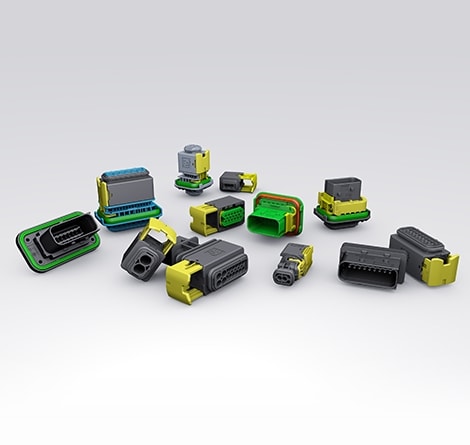

Our Heavy Duty Sealed Connector Series is designed to meet the rigorous demands of the commercial vehicle industry and off-road applications that require the highest standards of performance. Made from a rugged UL94 V-0-rated thermoplastic, Heavy Duty Sealed Connector Series have an integrated secondary lock with a poka-yoke feature that can be used for inline or flange-mounted applications in a wire-to-wire or wire-to-device configuration. Rated to IP67 and IP6K9K (when used with a backshell), Heavy Duty Sealed Connector Series are available in 5 housing sizes with 4 keying options. They are offered in arrangements ranging from 2 to 18 positions. Solutions for CAN bus architecture are also available. Accessories include backshells, protection caps, cavity plugs, and fixing slides.

Product Features

- Accepts contact sizes 6.3/4.8K (up to 40 amps), 2.8 (up to 40 amps), and 1.5K (up to 20 amps) and MCON 1.2

- 6.00-0.20 mm2

- 2, 3, 4, 6, 7, 8, 10, 12, 13, 15, 16, and 18 cavity arrangements

- In-line, flange or PCB mount

- Rectangular, thermoplastic housing

- Slide lock for mating

- An integrated secondary lock confirms contact alignment and retention

- Meet CAN Bus protocol specifications according to SAE J1939 standard

- Available accessories: Backshells, fixing slides, protection caps, blind plugs and sealing plugs

Product Benefits

- Optimize applied costs with AMP MCP 1.5K, 2.8, and 6.3/4.8K and MCON 1.2 contacts. The shared family supports a broad range of heavy-duty applications with high current capacity.

- Protect from dust, water, and overspray with up to IP69K rugged sealing capabilities.

- Easily insert and extract contacts and enjoy trouble-free maintenance with individual wire seals designed to crimp at the base of the terminal.

- Quickly verify the terminal position with the integrated secondary locking device and poka-yoke system, using a reliable assembly process.

Key Applications

As they are sealed and robust these connectors are serving multiple applications in your industrial and commercial vehicles.

Key Industries

Our heavy-duty sealed connector series is used in multiple industries thanks to its robustness and ease of installation.

Truck

Bus

Construction Equipment

Agricultural Equipment

Special Vehicle

Automotive

Material Specifications

- Flange Seal: Silicone rubber

- Seal for Secondary Locking: Silicone rubber

- Housing: Glass-filled PBT

- Secondary Locking: Glass-filled PBT

- Slide Lock: Glass-filled PBT

Performance Specifications

- Current: Up to 40 amps.

- Temperature: Operating at temperatures -40°C to +140°C.

- Durability: Up to 10 cycles (tin), up to 50 cycles (silver), and up to 100 cycles (gold), see individual product specifications for additional details.

- Insulation Resistance: 500 volts DC, test acc. to ISO 16750-2 (4.12).

- Immersion: IP67 rating, IP6K9K with cover, for tab housings with flange, only by observing mounting instructions.

- Random Vibration: No physical damage to housings and contacts, no derogation of function; the connection may not open at 177 m/s2, 94 hours for every three axes. See product specifications 108-94020 for full specifications.

- Voltage: Up to 42 volts DC.

- Dielectric Withstanding Voltage: No flashover or breakdown between adjacent contacts and outer contour of the housing permitted at 500 volts AC and 50 or 60 Hz for 60 seconds.

- Flammability: A product with UL 94 V0 rated material is available.

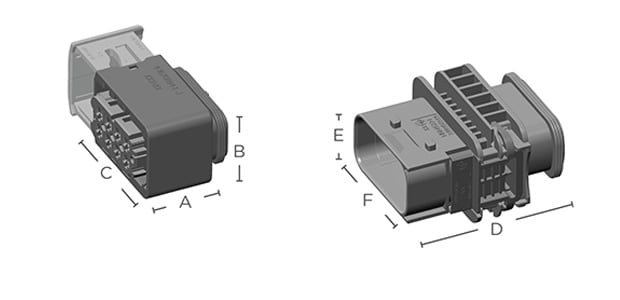

Heavy Duty Sealed Connector Series Dimensions

| Group | Receptacle Housing | Tab Housing | ||||

|---|---|---|---|---|---|---|

| Overall Length A | Overall Height B | Overall Width C | Overall Length D | Overall Height E | Overall Width F | |

| A | 1.23 (31.3) | 0.73 (18.5) | 1.02 (26.0) | 1.64 (47.1) | 0.75 (19.0) | 1.09 (27.6) |

| B | 1.23 (31.3) | 1.01 (25.7) | 1.19 (30.2) | 1.64 (47.1) | 1.06 (27.0) | 1.09 (27.6) |

| C | 1.23 (31.3) | 1.01 (25.7) | 1.23 (31.2) | 1.64 (47.1) | 1.06 (27.0) | 1.28 (32.6) |

| D | 1.23 (31.3) | 1.01 (25.7) | 1.54 (39.2) | 1.64 (47.1) | 1.06 (27.0) | 1.60 (40.6) |

| E | 1.23 (31.3) | 1.01 (25.7) | 2.02 (51.2) | 1.64 (47.1) | 1.06 (27.0) | 2.07 (52.6) |