Sealing, Protection & EMC Design Considerations in E-Mobility Applications

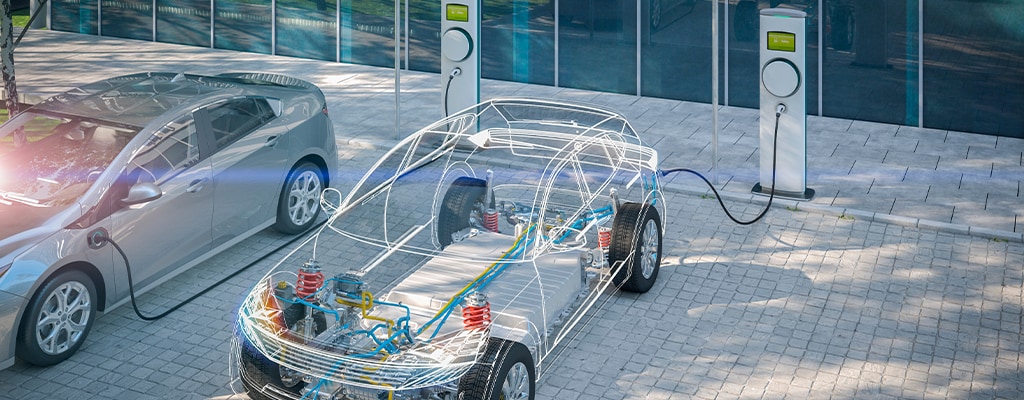

Download WhitepaperEV and hybrid applications often require manufacturers to design robust, resilient, and lightweight vehicles that address the performance demands of the transportation vehicles market. In the industrial space, this is further compounded by the need to operate in harsh conditions such as heavy rain, snow, and extreme temperature changes on a daily, constant, and seasonal basis.

But that’s not all. Major market needs around safety, connectivity, and efficiency are also impacting manufacturing specifications in the EV and hybrid vehicle space.

Design engineers must address the voltage, current, sealing, vibration, chemical compatibility, and temperature challenges associated with manufacturing all types of EV and hybrid vehicles. This means choosing protective products that can work within increasingly complex designs, as well as withstand the harsh environments inherent to vehicle operation.

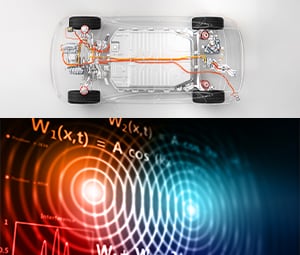

In addition to protecting and sealing critical components, product designers need to understand that all active electronic devices have the potential to emit electromagnetic radiation in the architecture of the vehicle and therefore also need to consider electromagnetic interference (EMI) shielding products to protect critical electronic components and systems from EMI. This is particularly true for designing highly integrated architectures where high voltage and high current systems are in close proximity to low voltage signal lines.