EMI Shielding Design Considerations at the Heart of Medical Equipment Compliance and Performance

Download WhitepaperAs technology evolves, EMI shielding becomes increasingly important. Interruption in medical device performance such as ventilators can be the difference between life and death. Without proper EMI shielding, medical devices, including life-support systems and essential monitoring equipment are vulnerable to signal noise, damage, or total functional impairment. A ventilator that doesn’t meet prescribed emission limits can have unfavorable consequences for other medical devices.

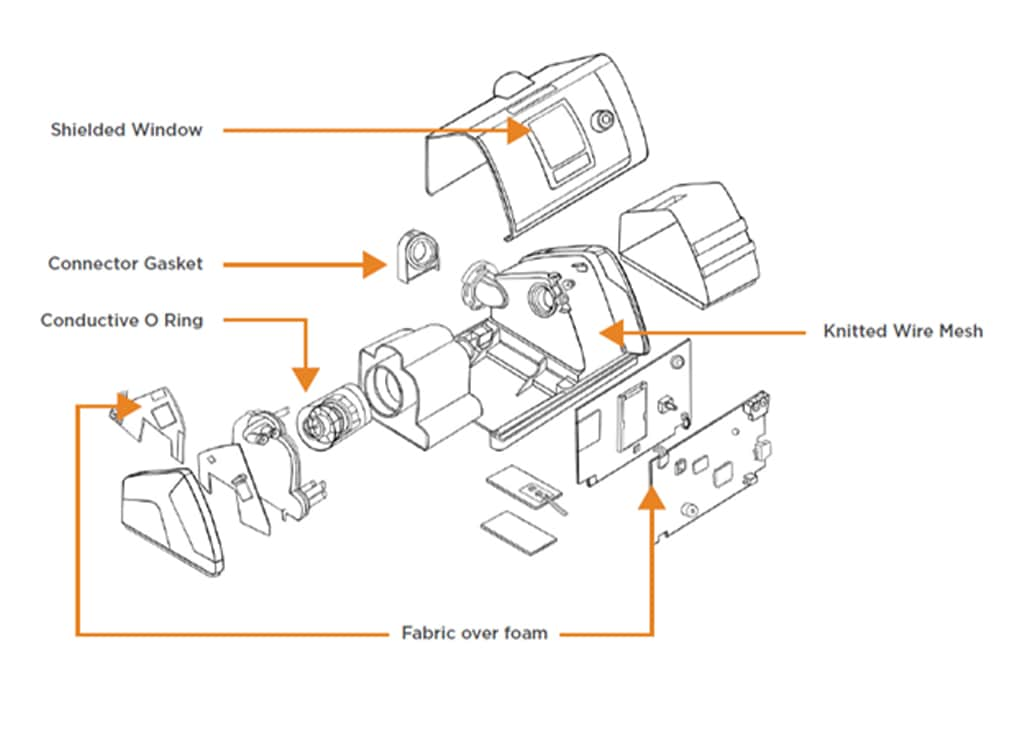

Therefore, EMI shielding, as a key component of engineering design, should be considered at all levels of design from the PCB layout to the enclosure. Engineers are faced with an array of shielding options to suit their needs at each design stage. Our experts will partner with you to identify the right solution to solve your Electromagnetic Compatibility challenges allowing you to optimize your design performance and compliance.

Potential Equipment Shutdown

Intermittent Failures

Metastable Logic

Another consequence could be the occurrence of metastable logic, typically caused by a logic gate getting stuck between states 0 and 1. This can trigger a firmware error, necessitating a manual restart of the machine.

Interruption in medical device performance such as ventilator can be the difference between life and death. Without proper EMI shielding, medical devices, including life-support systems and essential monitoring equipment are vulnerable to signal noise, damage, or total functional impairment.

There are many types of EMI Shielding capable to protect all the critical components and increase performance reliability and value to medical professionals. With the current trends and demands on the medical industry, TE Connectivity’s EMI shielding technology with costs and quality of life at the heart of our manufacturing.