Single Wire Seals and Cavity Plugs for Automotive Connectivity

TE Connectivity’s (TE) broad portfolio offers a variety of different seals and cavity plugs for most wire sizes and connector cavities designed for automotive connector systems. They effectively prevent contaminates from entering the connectors, enabling safe and reliable connections.

Global

Global in-house capacity and coverage.

180+

Different seals and plugs for various wire sizes and cavities.

1 Stop

One-stop-shop for complete sealed connector system.

Single Wire Seals

TE Connectivity’s (TE) broad portfolio offers a variety (>180) of different seals and cavity plugs for various wire sizes and connector cavities designed for automotive connector systems. They effectively prevent contaminates from entering the connectors, enabling safe and reliable connections.

Thanks to our global manufacturing footprint and integrated supply chain, TE offers local-to-local supply for complete one-stop-shop sealed connector systems (terminal, connector, seal, and cavity plug). In addition, TE also provides family/mat seals, radial seals to complete your automotive connector requirements.

Single wire seals (SWS) have three different interfaces that use a three-lip configuration that creates layers of redundant sealing. SWS elements are generally made of liquid silicon rubber that offers high mechanical resistance and can work in a wide window of operating temperatures. The material hardness is typically specified as 50-60 Shore A (ShA) durometer and is optimal in providing the necessary compression, tear resistance, and durability needed for automotive applications.

The Single Wire Seals consist of three sealing interfaces:

Seal-to-Wire

The SWS is automatically placed on the wire where the outer diameter is within a well-defined range. This wire size is linked to the hole dimension of the SWS and is smaller in diameter to have geometrical interference needed to create the sealing. Seal geometry with two to three lips is generally adopted to provide a point-distributed sealing pressure against the cable.

This geometry allows three main advantages:

- Multiple sealing surfaces are better than a continuous sealing surface due to possible cable shape defects.

- The inner lip profile assures good sealing even when the wires are bent.

- Fluid pressure drops occurs from the first lip to the second lip. For this reason, fluid infiltration is avoided.

Seal-to-Contact

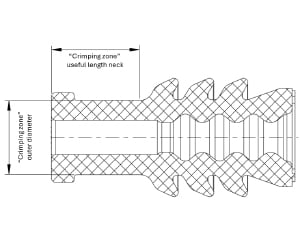

The seal is crimped onto the contact. The outer diameter of the "crimping zone", the useful length of the neck where the terminal crimp hugs the silicone, and the presence or not of a collar (defined by design) are important parameters to ensure the contact barrels close and retain the SWS without generating cuts on the surfaces. The crimp quality is fundamental to ensure a proper seal-to-contact interface.

Seal-to-Cavity

The sealed contact is inserted into the cavity. The difference between the outer diameter of the seal and the cavity diameter generate a radial compression of the rubber element and the consequent sealing pressure at the interface. This interference causes additional closure pressure on the wire interface increasing the tightness level towards the cable.

Single Wire Seal Portfolio

Cavity Plugs

TE’s cavity plugs are used to seal a single connector cavity where no contact is used and can be used in either female or male housings with some that are cavity compatible with competitor terminals. The geometrical profile is fully sealed from the single wire seal element with the exception that it does not have an inner hole for wire.

Rubber material selection is very often limited to the silicone rubber with a ShA hardness range that is generally between 50 and 60; lubricant in the rubber raw material is generally not requested to increase the seal retention into cavity, as there is not any mechanical constraint for this rubber element.

Cavity Plugs Portfolio

BENEFITS

Reliable, Safe and Sealed Connector Solutions Provider

- Broad, complete portfolio providing a one-stop-shop solution for automotive applications.

- Increased performance, safety, and longevity of your electrical connection field.

- IP67 waterproof protection.

- Cavity compatible with some competitor terminal systems.

- Global manufacturing footprint and integrated supply chain.

- Harness automation ready.

- 48V architecture enabled.

Single Wire Seals (SWS)

- Lip configuration creating multiple layers of redundant sealing.

- Silicon rubber offers a high mechanical resistance in numerous operating temperatures.

- Material hardness specified at 50-60 Shore A (ShA) durometer providing optimal compression, tear resistance and durability required.

- Lubrication for wire passage through the seal to reduce damage when inserted into the cavity.

Cavity Plugs

- Silicon rubber material selection with a ShA hardness ranging between 50-60.

- High level seal retention into cavity.

e

e

e

e

e

e

e

e

e

e