Miniaturized PicoMQS Vehicle Interconnection System

TE Connectivity’s (TE) automotive-grade PicoMQS miniaturized automotive connector system is the newest addition and solution to the successful NanoMQS and MQS product families, making it best-in-class for space constrained signal interfaces requiring optimized performance, minimized packaging and ease of manufacturing. PicoMQS interconnection system enables severe space-constrained electronic components, shorter wires and a reduced total connector package.

1.27

1.27mm Pin-Pitch

78%

Reduced packaging weight (compared to MQS)

LV214

Smallest LV214 qualified crimped connection with Class 2 vibration stability

Product Features

PRODUCT FEATURES

- 1.27mm pin-to-pin pitch

- SG2 Vibration Grade

- 0.13mm² to 0.22mm² wire range

- Current capacity: 4A (90°C)

- Mating for 0.5mm x 0.4mm blade size

- S-bended pins header design

- Max. temperature 130°C (Sn) / 150°C (Ag)

- Automotive standard compliant (LV214)

- Locking Lance Design

- Primary and secondary contact locking

- Click-audible connector position assurance (CPA) possible

- Clearance and creepage distance on a level of 12V

- FFC terminal coming soon

Available PicoMQS Components

Benefits

BENEFITS

- Automotive-grade robustness with Class 2 vibration stability with maximum temperature of 130°C (Sn) / 150°C (Ag). 0.22 wire, continuous current capability up to 4A @80°

- Best-in-class miniaturization/space-reduction for space-constrained signal interfaces with 78% reduced packaging weight (compared to MQS), 1.27mm pin pitch (30% reduction), and 55% reduction in crimp length with complete LV214 qualification

- Smallest LV214 qualified crimped connection with anti-scooping features, secondary locking system, Kojiri connector design

- Manufacturing ease, quality and cost efficiency with automated pin insertion and S-bending solder pin design for camera control for header board position with a reduced pin length by 4mm (42% shorter length)

MQS Product Family

PicoMQS Terminals

The PicoMQS receptacle contact is typically used to connect sub-systems or modules, known as blackboxes, in a wide range of applications including headlamp and steering units. Additional to blackbox (headlamps and power electronics) applications it is used for battery applications. In contrast to interconnection systems for consumer electronics, which are occasionally used for this type of application, the package optimized PicoMQS receptacle contact, and crimp is designed to meet vibration resistance severity level 2 according to LV214. Still, PicoMQS carries up to 4 amps with a 0.22 wire.

Features & Benefits

- 0.13mm2 to 0.22mm2 wire range

- Mating for 0.5mm x 0.4mm blade size

- Automotive standard compliant (LV214)

- SG2 Vibration Grade (unsealed)

- 55% Reduction in crimp length

- Locking lance design

- Primary and secondary contact locking

- Max. temperature 130C (Sn) / 150C (Ag)

- FFC Terminals for complex space constraints and automated assembly of modules (coming soon)

PicoMQS Connectors

TE Connectivity’s PicoMQS connector system maintains a robust and reliable connection in high-vibration environments and is validated to SG2 vibration grade, making them ideal for blackbox (headlamps and power electronics) and battery applications, to name a few. Standard versions will include single-row connectors (2-10 positions).

Features & Benefits

- Up to 78% reuced packaging (compared to MQS)

- Kojiri connector design

- Robust Anti-scooping features

- Primary and secondary locking system

- LV214 qualified

PicoMQS Headers

Based on TE Connectivity’s (TE) highly successful MQS and NanoMQS connector system, PicoMQS headers are designed for complex space-constrained automotive applications offering a pin pitch of 1.27mm enabling a PCB footprint reduction by up to 78% vs TE’s MQS. TE’s S-bending solder pin design offers compromise between space usage and camera inspect ability.

Features & Benefits

- S-Bended pins save up to 30% of PCB space (compared to Z&J type)

- Surface Mount Technology

- Reduced pin length by 4mm (42% shorter length)

- Through-Hole technology available

- Press-Fit Pin Technology (NanoMultispring)

- 1.27mm pin pitch (30% reduction)

- 2 – 10 positions

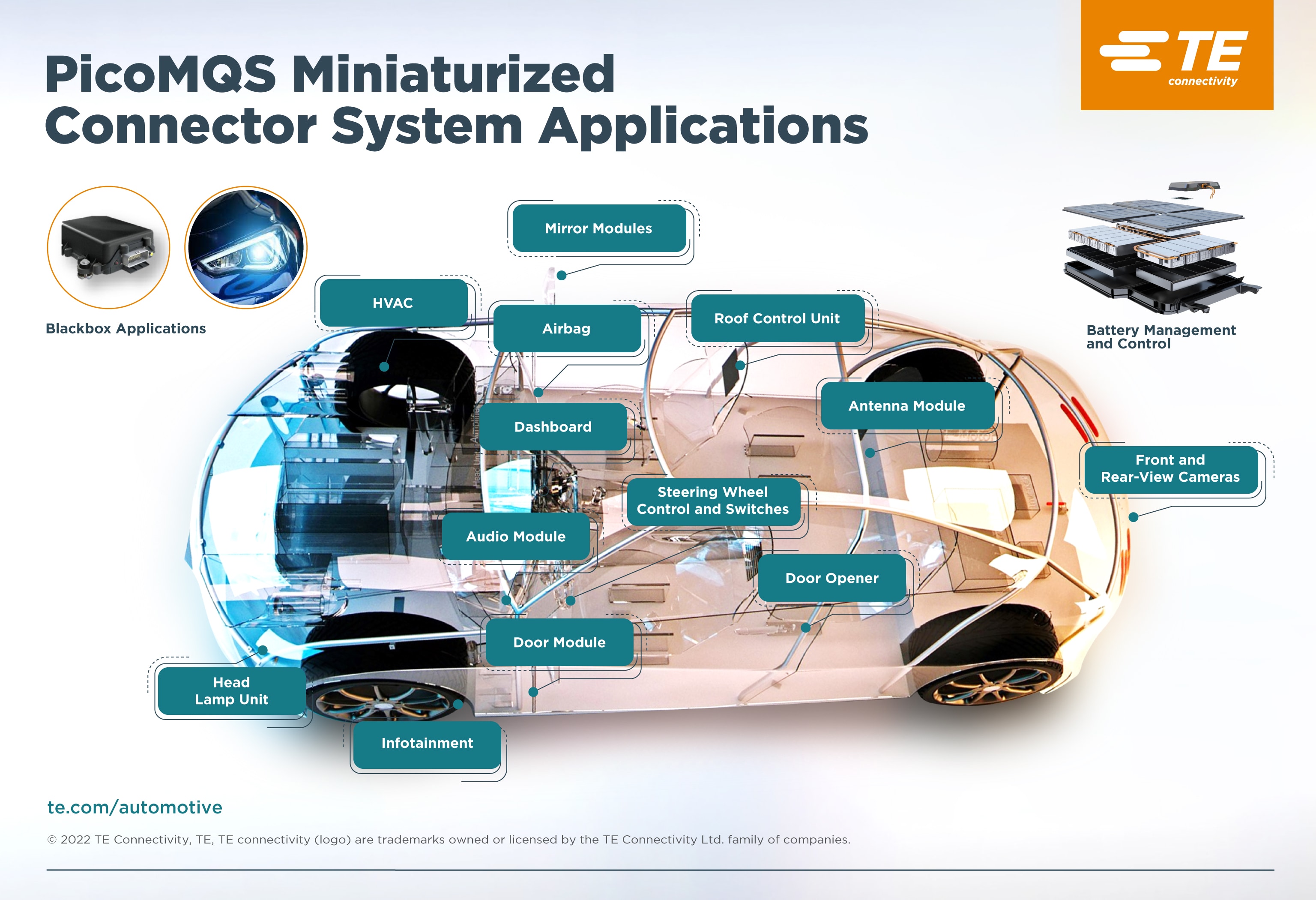

PicoMQS Automotive Applications

Wire Termination and Crimping

APPLICATION TOOLING

The challenge of achieving automotive grade robustness is not limited to connector components but also extends to the wire termination and crimping process. That means application tooling also plays a vital role in providing true automotive vibration resistance. Smaller wire and terminal sizes create much greater complexity in the termination process. Thinner wires are extremely flexible and can be difficult to maneuver, accurately position and properly strip.

Additionally, smaller terminal sizes require precision wire placement into the wire barrel to prepare for a quality crimp. Any manufacturing tolerances between the crimper and anvil tools can result in flash, twisting, or other non-conformances. That means, as terminals miniaturize, the entire wire handling and crimping process must be re-imagined to deliver true automotive-grade crimp quality.

For PicoMQS contacts to achieve this, we have been collaborating with our Application Tooling department early in the development stage, to ensure we can offer a complete component and tooling solution. In the case of crimping, it means our tooling solutions are pre-tested against automotive standards requiring no further OEM certification.

FFC & FPC Cable Termination Machine

For PicoMQS FFC Terminal

The new semi-automatic FFC and FPC termination machine provides a new high-performance crimping solution for PicoMQS FFC Terminal with quality process control, compatibility and parameter visualization.