Trend Insight

48V Electrical and Electronic Systems

As OEMs increase electronics, power demands grow, leading to a shift to 48V systems. Providing the same power as 12V with less current, 48V enables lighter wiring, boosting efficiency, reducing weight, and enhancing sustainability by minimizing materials and power loss.

48 Volt Connector Requirements

For connectors in 48V electrical systems, the primary requirement is an optimal pin pitch that ensures adequate creepage and clearance distances to prevent arcing. Additionally, these connector systems need robust locking mechanisms to prevent accidental disconnection, maintaining secure connections even under harsh conditions. Meeting automotive specifications for durability and reliability, these connectors are designed to handle the higher voltage demands safely and effectively, ensuring consistent performance in demanding automotive environments.

Connectivity Solutions for 48V Architectures

Automotive low-voltage electrical/electronic (E/E) architecture is shifting toward a higher 48-volt standard, and TE Connectivity is well-prepared to support this transition. With a range of comprehensive solutions tailored to meet the demands of 48V systems, TE offers the advanced technology and expertise needed to power the next generation of automotive innovation. This strategic positioning enables TE to help customers achieve greater efficiency, reduced weight, and enhanced overall performance as the industry moves toward more sustainable and powerful 48V architectures.

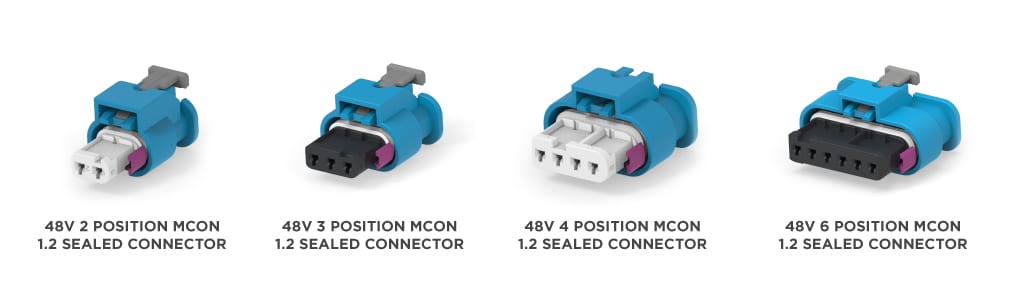

48V Connectors

48V Applications

- HVAC eCompressor

- Active suspension

- Steering-by-wire

- Braking-by-wire

- Fans

- Electric catalytic converter

- Pumps

- Seat/window heater

- PTC heater

- Heat pump

- ADAS computer

Related Products and Technologies