The future calls for fully automated, end-to-end connection solutions. Let’s transform the way the world makes things—beyond sensors and connectors. Together, we can move the world forward.

Expanding the possibilities of automation

From cobots and robots to factory IoT, TE is a longtime partner in transforming industrial technology across virtually every industry. Together, we can build a world of safer and more productive workplaces. Where products can build and deliver themselves and IoT connects our automated tech from anywhere in the world. TE is the partner to engineer these application possibilities into reality.

Product Manager, Sensors - Force/Torque/Multi-Sensor

Robots and cobots have become our everyday coworkers. From healthcare to home maintenance, advanced industrial tech is operating alongside humans to create a safer, more precise and productive work environment.

Principal, Standardization & Consortia, Industrial Solutions

Industrial IoT is a revolution for the modern workplace. For virtually every industry, industrial IoT connection provides advanced visibility and efficiency with actionable data. These connection solutions improve worker safety and increase production uptime with predictive maintenance capabilities.

What is Industrial Automation?

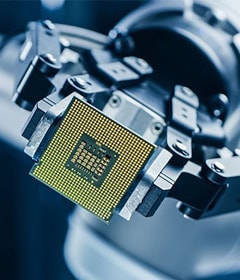

As the next great leap forward in mechanization, industrial automation integrates data into the manufacturing equation through high-input sensors and sensor infrastructures. Machines like robots and cobots then utilize the data to advance processes in manufacturing, quality control, and material handling.

Why Does Industrial Automation Matter?

It can greatly lower your operating costs while increasing both efficiency and productivity throughout your processes. Industrial automation paired with robots alleviates human error and takes humans out of hazardous working conditions. The data can also give robots greater flexibility in handling a larger range of tasks. Overall it provides high information accuracy through automated data collection.

How Do I Integrate Automation?

Identify the appropriate automation system and associated tools—processes that have both transaction (repetitive tasks) and decision parts will benefit the most from automation.

Then, based on the requirements, you can choose from various programmable automation platforms, such as distributed control systems and flexible manufacturing setups that include robots. Supplement this with CAD and logical control systems for easy operability.

Be sure to choose the right stakeholders in this journey. Partnerships with relevant contractors/suppliers will ensure a seamless experience, from designing the right automation strategy to testing and implementation of automation processes, in original environment conditions.

Once functional, create training plans to ensure your staff is properly trained to operate the new system. A contingency plan that instructs how to manually operate the system in case the system fails should be put in place. Sustain the automation process by creating a mindset in the organization to modify automation processes based on changing needs in the environment.

e

e