Data centers require architectures that process increasing amounts of data more quickly and efficiently.

Read the full story

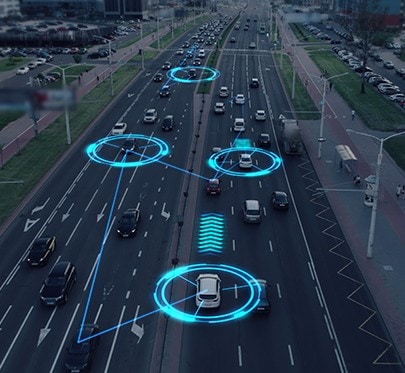

With the rise of generative artificial intelligence (AI), data centers have become an increasingly critical part of the world’s technological infrastructure — and a growing consumer of electricity. Even small-scale improvements involving the types of cables, connectors, and heat dissipation equipment used can have a huge impact on the amount of energy data connectivity systems use, helping increase data center sustainability.

Move data more efficiently to support AI technologiesTE Connectivity empowers engineers for innovation in industrial technology – by designing and manufacturing sensor and connectivity solutions for the technology that is enabling a safer, sustainable, productive, and connected world. As the go-to engineering partner for today's innovation leaders and technology entrepreneurs, we are helping solve tomorrow's toughest challenges. Our electrical and electronic products are engineered to reliably connect and protect the flow of data, power, and signal – in electric vehicles and aircraft, digital factories and smart homes, and life-saving medical devices, efficient utility networks, and the global communications infrastructure. As a global electronics company with 80 years of experience in developing innovative solutions for complex industrial technology applications used in harsh environments, our broad and diverse team of industry experts includes electrical and mechanical engineers who focus on designing electronic components and electrical components manufactured for reliability, safety, and sustainability, offering technological solutions that help empower the potential of people to drive innovation in the technologies transforming how people live, work, and connect.

Meet TE Experts at Events Worldwide

Find Us at Shows Near YouQuick access to top-searched products

- RJ45 Connectors

- USB Connectors

- AMP Connectors

- MQS Connectors

- DEUTSCH Connectors

- FAKRA Connection System

- FASTON Terminals

- MATE-N-LOK Connectors

- M12 Connectors

- Heavy Duty Sealed Connectors

- DEUTSCH DT Connectors

- Relays - Auto, Power, Signal

- RF Connectors - BNC & SMA

- Ring & Spade Terminals

- AMPMODU Connectors

Featured Tech Explainers

Our Approach to Business Innovation & Inclusion

Performance Sustainability

Our commitment to sustainability includes helping our partners innovate sustainably.

Supplier Diversity

Learn about our program for strategically empowering diversity-owned suppliers.

Industrial Tech Index

Our global survey reveals innovation challenges and opportunities for success.

e

e

e

e

e

e

e

e

e

e

e

e

e

e