Our EMI shielding solutions offer various conductive fillers that are designed to ensure galvanic compatibility while providing low contact resistance between mating surfaces. Our conductive elastomers are fully cured silicones or fluorosilicone loaded with a variety of highly conductive particles providing superior EMI/RFI shielding performance combined with excellent environmental sealing.

Types of EMI Shielding

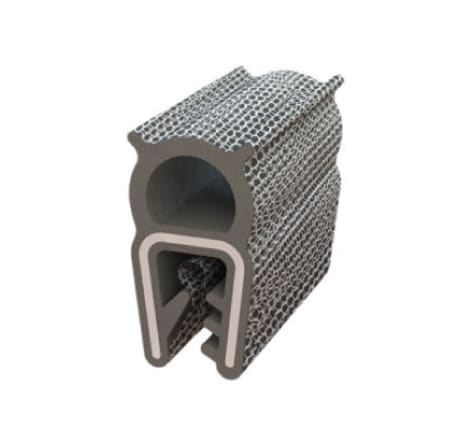

Conductive Elastomers

Electrically conductive elastomers are made from silicone or fluorosilicone loaded with highly conductive particles such as silver-plated aluminum, silver plated copper, nickel coated graphite and pure nickel.

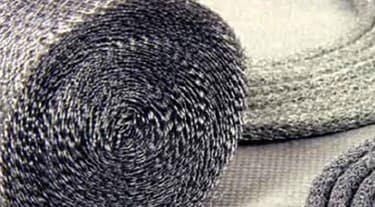

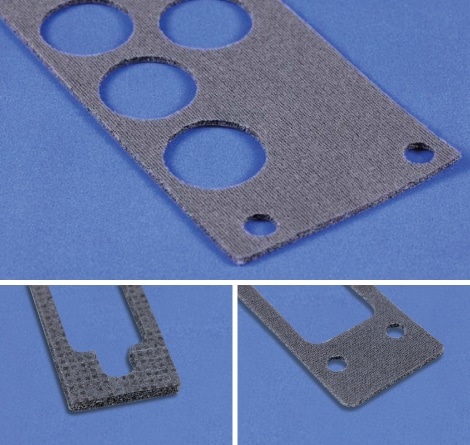

Knitted Wire Mesh

Knitted wire mesh gaskets provide an excellent cost-effective EMI gasket, providing shielding in the magnetic as well as electric fields.

Oriented Wires in Silicone

Solid and sponge silicone populated with vertically oriented Monel or aluminum wires up to 140/sq cm. Provides excellent shielding with electromagnetic protection (EMP) survivability and will also provide an environmental seal.

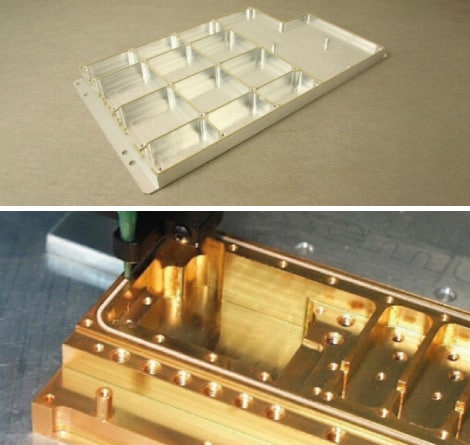

EMI Shielding Ventilation Panels

EMI shielding vent panels or attenuvents are made from aluminum or steel honeycomb mounted into a frame. Many aluminum frame styles are available together with different thicknesses and configurations of honeycomb to meet different shielding requirements.

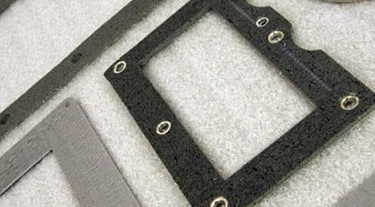

Connector Gaskets

Engineered for a wide range of standard MIL-Spec connector gaskets. Different materials are available to meet the demands of EMI shielding, environmental sealing, galvanic compatibility, and fuel/oil resistance.

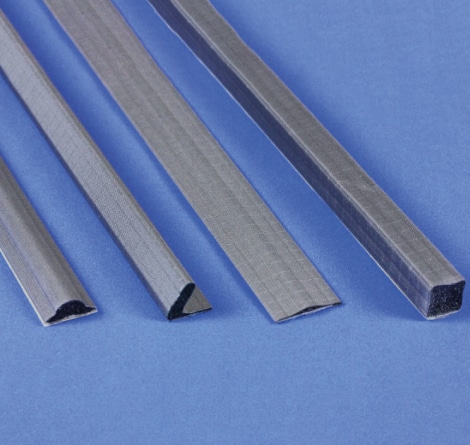

Jam Nut Seal

Made from extruded sections cut to length and the two ends joined by vulcanization to ensure a durable bond and maintaining the integrity of the seal.

e

e