Save space while maintaining reliability

We offer a wide variety of surface mount resistors, also known as surface mount devices (SMD), including resistors suitable for pulse, surge, and voltage applications. Our standard thick film surface mount resistors offer power ratings of 6W and molded resistors to 7W. Our small SMD power resistors save space from traditional leaded products and offer a range of SMD thin film resistors with both NiCR and TaN film technology.

Find by Element and Type

Surface Mount Resistors

- Thin Film Precision Surface Mount Resistors

- Thick Film General Purpose Surface Mount Resistors

- Thick Film Power Surface Mount Resistor

- Wirewound Power Surface Mount Resistors

- Precision Resistor Kits for Surface Mount Resistors

- Thick Film Current Sensing Surface Mount Resistors

- Thick Film Precision Surface Mount Resistors

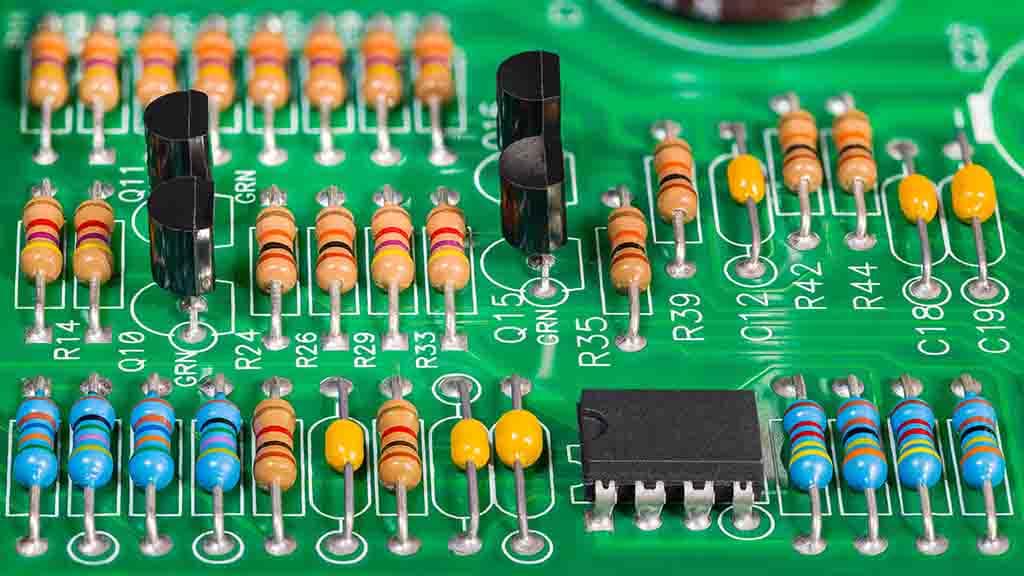

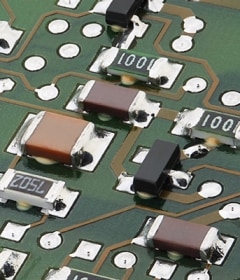

A surface mount resistor is a tiny rectangular ceramic body with silver conductive edges on either end. Also referred to as surface mount technology, an SMD resistor offers advantages in saving space on printed circuit boards (PCBs). It features the resistance value code printed onto it, where there is space. Solder paste is printed onto the mounting pads of a PCB, and the resistors are placed automatically onto these pads by pick and place equipment. The whole board is then passed through a reflow oven which melts the solder into place, making the contacts.

A surface mount resistor provides the same functionality as the more traditional axially leaded resistors but has a lower power dissipation capacity and oftentimes a lower stray inductance and capacity. Surface mount resistors can be thick film, which is most commonly used, thin film, which offers accuracy and stability, metal strip, for current sensing, or wirewound, which is molded construction as opposed to a flat chip.

Surface mount resistors are used in large quantities and are the preferred resistor for use in electronics equipment, because of the small size and high reliability. Surface mount resistors are commonly used in telecommunication, automotive, and medical equipment, as well as in personal devices, displays, and advanced technology research instruments.

Select Applications

Surface Mount Resistors

SMD Current Sense Metal Chip Resistor

Type TLMQ Series

TE Connectivity (TE) has extended our low ohmic metal chip resistor TLM series with the High Power TLMQ. This series is designed for current sense circuits in power electronic systems which now also has a more advanced primary overcoat applied on both its top and bottom side which offers higher reliability, accuracy and durability. Supplied as standard on tape and reel for automatic insertion processes.

Product features

- High power rating in small size

- Metal foil construction

- AEC- Q200 compliant

- Lead free to meet RoHS Requirements

- Low resistance resistor for current detection

- Advanced primary overcoating

See SMD Current Sense Metal Chip Resistor - Type TLMQ Series

Thick Film High Precision Resistors

Type RT73 Series

TE Connectivity (TE) brings you it’s metal-glaze high precision thick film resistor range, type RT73 series available in four different packages with standard resistance values offered in the E96 and E24 series. The resistance tolerance specifications are from 1% to 0.1% with low temperature co-efficient of resistance (T.C.R. making the RT73 series suitable for use in automotive, measuring equipment and industrial measurement applications.

Key Benefits

- Metal glazed film

- Lead-free and MSL level 1 moisture resistance

- Miniaturized design for efficient use of space in modern electronic devices

- Exceptional precision and accuracy in maintaining specific resistance values

- Ideal for applications where precise current control is essential

- AEC-Q200 qualified and compatible for use in automotive applications

SMD Moulded Power Resistors

Type SMQ Series

TE Connectivity (TE) introduces AEC-Q200 Qualified version of our SM series surface mount power resistor, also giving

UL94V0 flame resistance. Available in 3 ratings up to 3 Watts and supplied on tape and reel for automatic insertion

process

SMQ Series

Key Benefits

- Available on tape

- Very wide value range

- Ideal for power circuitry

- Available in 3 ratings up to 3 watts

- Flameproof coating UL94V0

- AEC-Q200 Qualified

Metal Film Precision MELF Resistor SMA-Q Series

Key Benefits

- AEC-Q200 qualified making it reliable for automotive applications

- Excellent overall stability

- Sn termination on the Ni barrier layer

- Tight tolerance down to ± 0.1 %• Extremely low TCR down to ±5 ppm/°C

- High power rating up to 1 watts

- SMD enabled structure

- Lead-Free and RoHS-compliant

- MSL level 1 ensures high moisture resistance

- Thin film technology

Frequently Asked Questions

FAQs about Surface Mount Resistors

Q: What are SMD resistors?

A: SMD stands for Surface Mount Device. An SMD is any electronic component that is made to use with Surface Mount Technology (SMT). SMT was developed to meet the ongoing demand for printed circuit board (PCB) manufacturers to use smaller components that are faster, more efficient, and cheaper. SMDs are smaller than through-hole resistors and instead of having wire leads that go through PCB, they have terminations that are soldered to pads on the surface of the board. This eliminates the need for holes in the board and allows both sides of the board to be used more fully.

Q: How are SMDs made?

A: SMDs are made by placing end connection electrode bases onto an alumina or ceramic substrate. The resistor is then fired to ensure the electrodes are held in place. Next, a film of resistive material is printed or deposited and the resistor is fired again. The resistor is then covered with successive layers of a protective coat that dry between applications. These layers prevent mechanical damage and ingress of moisture and other contaminants. Finally, a marking is placed on the resistor if the surface is large enough. The resistors are packaged in a form of blister roll for use on pick and place machines, or they can be supplied as loose components.