Splice Wire With Confidence

Whether you need to splice 30 AWG solid copper magnet wire or 4/0 stranded aluminum wire, our broad range of splices allow you to splice solid or stranded wire - with copper, aluminum, or a combination of both. We offer crimp, insulation displacement connection (IDC), and other wire splicing types technology, which you can apply manually or with semi- or fully-automated equipment. Engineered for reliability, our portfolio of electrical wire splices provide you with many types of splices that offer cost-effective solutions for when you need to make millions of splices or a few repair splices.

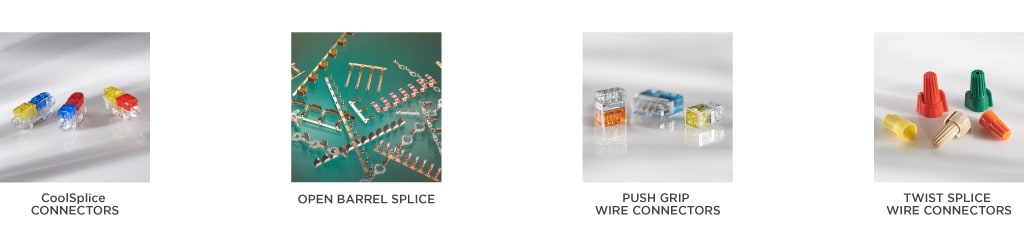

Featured Products

Splices

The CoolSplice connectors elegantly combine reliability with ease of termination. The CoolSplice connector from TE is suitable for splicing 22 AWG to 18 AWG (0.34 mm2 - 0.75 mm2) solid and stranded wire. A common pair of pliers is used to push-button terminate insulated wires into an insulation displacement crimp contact. An industry proven reliable connection is provided and visually confirmed through the clear sidewall of the CoolSplice connector.

The Push Grip Wire Connectors are insulated splice connectors for electrical installations. These poke-in wire splice connectors accept wire strip lengths ranging from 3/8 - 1/2” [9.5 - 13mm] and provide visual termination of 22 - 12 AWG solid, rigid stranded and tin bonded stranded wires. These splices are color coded for easy identification, compact in size to fit into tight spaces and the wires are extractable, if required.

Twist Splice wire connectors can be used in almost every type of residential and commercial application where multiple wires need to be brought together for a reliable termination. TE wire connectors, which include Wire Grip, Wing Grip, Twist Grip, Ground Grip and Cap Grip connectors, are designed to meet industry standard color-coding specifications and terminate the corresponding range of wire sizes. The screw-on wire connectors contain a live-action square spring which draws wires deep into the spring for a safe, positive “grip” of the wires.

Open Barrel Splice

The open barrel rings and spades are manufactured in strip form and supplied on reels for Automachine termination. In the standard “F” crimp configuration, the open barrel consists of two “U” shaped wings that are crimped around the conductor strands and butted together into a tight seam. The crimping action of the TE's application equipment is a precise operation that creates the proper crimp with each cycle of the machine. This ensures uniformity of all the crimp terminations.

Frequently Asked Questions

Electrical Wire Splices

Q: Are you using solid or stranded wire?

A: Stranded wire with equal strand diameters provide optimal crimp performance. Stranded wire of equal strand diameter ensures optimum crimp compression and avoids any voids in the crimp. We understand this is not always practical for every application, wires of different strand diameters as well as solid stranded wire may be used in many applications. Consult your sales representative if you have further questions.

Q: What size wire are you using?

A: Generally the wire size will be determined by the current demanded. Different applications will require different wire sizes. How much current will the connection see? Continuous current or intermittent current? What environment will the wire be subjected to? Temperature requirements? All these questions need to be answered in order to select the correct wire material and correct wire size.

e

e

e

e

e

e

e

e

e

e