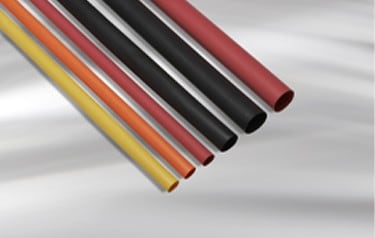

Orange Heat Shrink Tubing

Orange Heat shrink tubing provides electrical insulation, mechanical protection, environmental sealing, and strain relief. Available in single wall tubing and dual wall tubing, our heat shrinkable tubing is engineered for use in numerous applications, including back-end connector sealing, breakouts, and connector-to-cable transitions. It is a solid alternative to taping, molding, or potting.

Whether designing for harsh outdoor environments or the home, design engineers across industries need ways to insulate components against heat and electric current, provide strain relief for connectors and splices, and protect and seal against water ingress, chemicals and abrasions. Heat shrink tubing can be the versatile choice to solve all these design challenges efficiently. It can also provide cosmetic improvement and organize and identify different wires and components quickly. Many design engineers and manufacturers may not realize that tubing can be used just as effectively and often more effectively as a protective cover, insulator, noise reducer and more in many applications and industries.

Why Choose TE’s Heat Shrink Tubing Products: Designed for Harsh and Rugged Environments

As design engineers address the sealing, vibration and temperature challenges associated with many harsh environment applications, it’s important to understand the benefits of heat shrink tubing

- Versatility and Durability: Heat shrink tubing is designed to improve the ability to keep out moisture, harsh chemicals and mechanical interference. It also provides strain relief, electrical insulation, mechanical protection and environmental sealing for applications such as back-end connector sealing, breakouts, connector-to-cable transitions, and is especially useful in cable harnesses.

- Quick Installation/High-Tech Performance: Heat shrink tubing has a faster application time than other products resulting in better performance. For example, when compared to tape, heat shrink tubing has been shown to shorten application time (from 180 seconds to 45 seconds), improve yield (from less than 90% to over 98%) and provide a higher operational temperature rating (125°C compared to 105°C.)

- Easy Installation: When heated, heat shrink tubing conforms to the size and shape of the substrate beneath, enabling quick and easy installation. Its high expansion ratio of up to 8:1 can also enable users and technicians to repair most damaged cable jackets without removing other components such as connectors.

- Safety: Heat shrink tubing products are designed to maximize safety. This can include variables such as thick-tubing to secure extra protection, various colors for easy identification and various levels of flame-retardancy to meet UL VW-1 flammability standards.

- Reliable, Robust Cross-linking Technology: Cross-linking technology modifies the molecular structure of a polymer, allowing the tubing to withstand high temperatures without melting — a critical factor in harsh ICT environments. Heat shrink tubing can provide a complete seal and its high mechanical strength makes it more resistant to impacts and abrasions.

- Offered in Single Wall and Dual Wall Heat Shrink Tubing: Single wall shrink tubing provides superior insulation strain relief and protection against mechanical damage and abrasion versus taping and molding in place. Dual wall tubing should be considered the top choice over taping, molding and potting for any circumstance where corrosion protection and sealing are required.